Ever had to explain to a customer why their expensive equipment isn’t working as promised? If you’ve been in that uncomfortable conversation, you know it’s not just about fixing a problem, it’s about rebuilding trust that may never fully return. When design fails, Design quality isn’t just an engineering goal, it’s a fundamental promise to every customer who relies on your equipment for comfort, safety, and peace of mind. A recent recall involving 1.7 million…

Clear and accurate drawings are the foundation of every successful project. Whether it is a machine part, HVAC equipment, electrical panel, or industrial system, engineers still rely heavily on 2D drawings to communicate design intent. Even though 3D models are widely used, 2D drafting remains essential for manufacturing, installation, inspection, and maintenance. SOLIDWORKS is one of the most trusted CAD tools for creating professional 2D drawings. With SOLIDWORKS drafting services, companies can convert complex ideas…

In precision manufacturing, accuracy is everything. Whether you are designing components for aerospace, automotive, medical devices, or industrial equipment, the success of a project often hinges on the quality of the CAD drawings provided to CNC fabrication teams. At Asset Eyes, we understand that well-prepared CAD drawings not only reduce errors and costs but also streamline production and ensure parts are manufactured exactly as designed.This guide walks you through everything you need from essential steps…

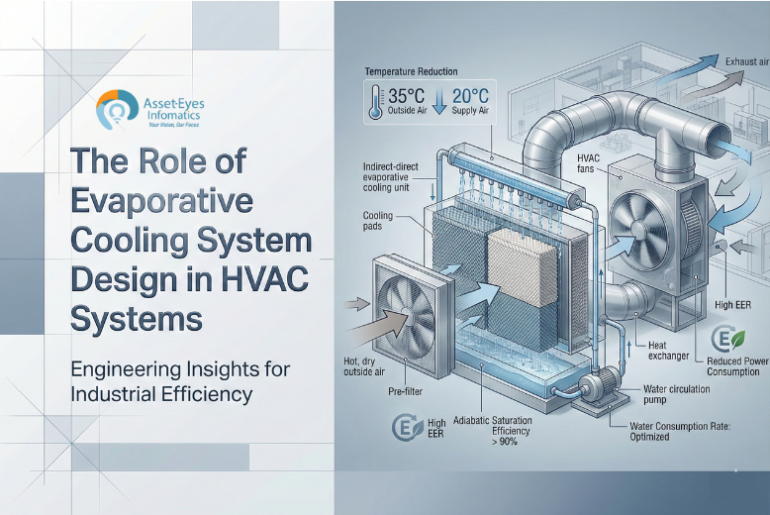

In the realm of modern heating, ventilation, and air conditioning HVAC systems, evaporative cooling has emerged as an energy efficient and sustainable cooling alternative particularly in hot, dry climates where traditional air conditioning can be costly and less effective. However, the success of any evaporative cooling solution depends not just on selecting the technology but on how well the system is designed, engineered, and implemented. At Asset Eyes, we view evaporative cooling system design as…

Modern architects face increasing demands in terms of design quality, speed, and accuracy. While creativity remains at the core of architecture, technical documentation such as CAD drafting is essential to bring designs to life. Managing drafting work internally can be time intensive and may limit an architect’s ability to focus on high value design tasks. Outsourcing CAD drafting services helps bridge this gap. By delegating drafting responsibilities to experienced professionals, architects can improve workflow efficiency…

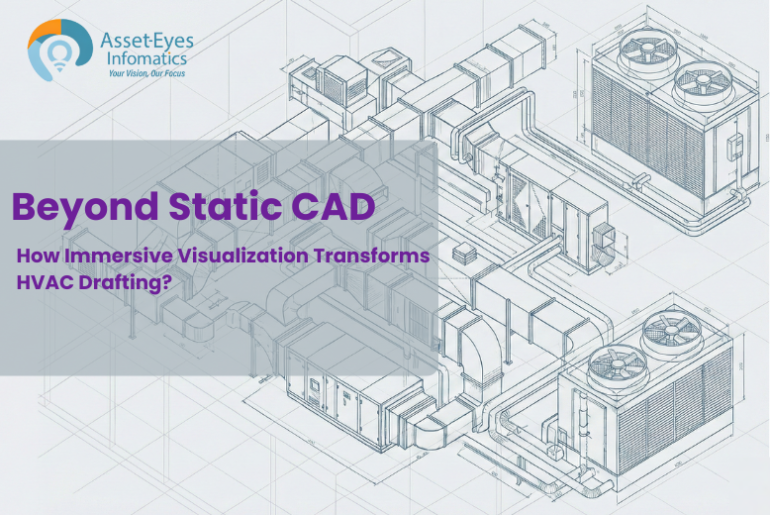

Have you ever watched a promising sales pitch fall flat despite your competitive pricing and perfect technical specifications? If you’ve experienced the frustration of seeing prospects nod politely through your presentation only to request “more time to think about it,” you’re facing one of the biggest challenges in complex HVAC equipment sales: helping customers truly understand what they’re buying before they commit significant capital. In today’s competitive HVAC-R manufacturing landscape, traditional sales presentations struggle to…

Ever watched a skilled technician squint at a control schematic, hesitate, then make their best guess at a connection? If you’ve seen that moment of uncertainty on your production floor, you know it’s not just about individual performance it’s about systemic inefficiency that quietly drains your bottom line. In HVAC/R manufacturing, the difference between documentation that looks professional and documentation that actually works can be measured in hundreds of thousands of dollars. A recent project…

Industrial facilities such as factories, workshops, and manufacturing plants generate dust, smoke, fumes, heat, and harmful gases during daily operations. If these pollutants are not properly managed, they can accumulate, creating an unsafe environment for employees and potentially damaging machinery. Poor air quality can also reduce productivity, affect product quality, and even result in legal or regulatory complications. industrial Exhaust system design are specifically designed to remove contaminated air from these spaces and safely discharge…

Has your team ever tried pulling a compressor out of a rooftop chiller skid at 3 AM during an emergency repair? If you’ve experienced the frustration of tight clearances, expensive crane rentals, and extended downtime, you’re not alone. The difference between a well designed lifting system and an afterthought can mean the difference between a two hour repair and a two-day ordeal involving external equipment, street permits, and frustrated facility managers. This post walks through…

Have you ever tried explaining a complex air handling unit layout or chiller plant configuration using only 2D drawings and static screenshots? We know that trying to paint a picture of what a piece of equipment looks like in the real-world isn’t an easy task, especially to stakeholders who don’t come from a technical background.Traditional CAD drafting often fall short of communicating design intent effectively across diverse teams from engineers to production staff to field…