Is EC fan really a One Stop Solution for the reduction of Carbon Footprint?

Of late lot many discussions are happening around on reducing the carbon footprint. In a typical industrial scenario, be it Manufacturing or a process Industry, Centrifugal equipments like Fans, Pumps and compressors (Centrifugal) are energy guzzlers. Amongst them, Centrifugal fans are most prominent and have a wide variety of applications such as general ventilation of a shop floor, HVAC, powder conveying system, dust collection system, combustion air for burners etc., Every small step ahead in improving the energy efficiency will have a great impact on reducing the carbon footprint.

Electronically Commutated (EC) Fans are seen as a viable option to improve the energy Efficiency of Fan. Although it is true to a great extent, in certain situations the expected results are not achieved. In the following paragraphs, let us discuss about such situations and concur that a specific analysis is required before replacing the conventional fan to an EC Fan. The Discussions are based on our practical experience with experts in the field of Energy Audits.

Prima facie, the Electronically commutated or permanent magnet motors are much efficient than the conventional EFF Induction Motors. By and large, conversion to EC / Permanent magnet motor should help. But we also need to look at the other contributing factors. Poor mechanical efficiency of the fan will obviously hurt the overall efficiency of the fan system (That is Fan and Motor coupled), which in turn affects the consumption of Electrical energy. Let us understand this with following case study.

Case Study

Equipment considered for case Study : Air Handling unit which is used to condition the air (maintaining temperature and Humidity)

Capacity of the AHU : 26,000 cfm x 2 Nos

Static Pressure to be achieved: 58 mm Aqua

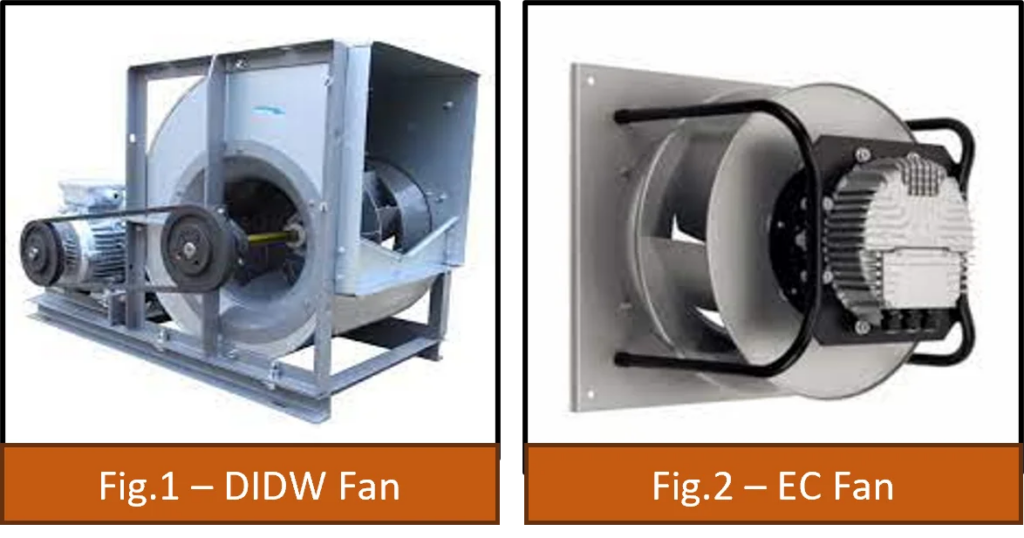

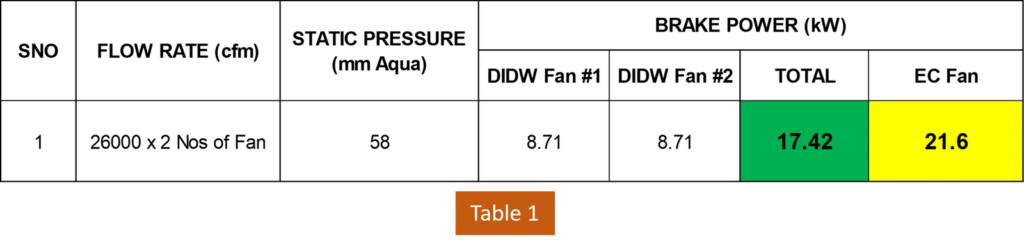

The following Table gives the comparison of power consumption between DIDW and EC Fan (refer Figure 1 & 2)

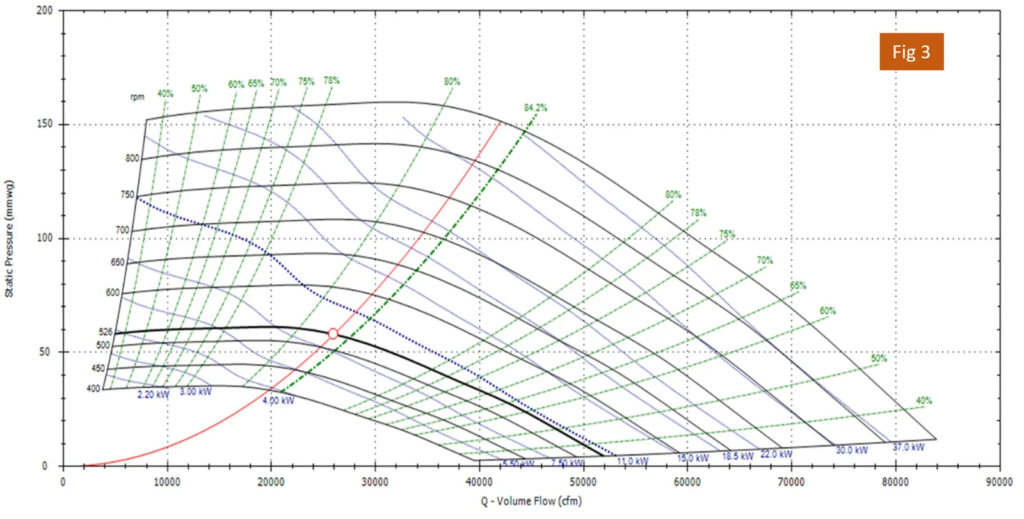

Performance curve of the DIDW fan for the given Parameter

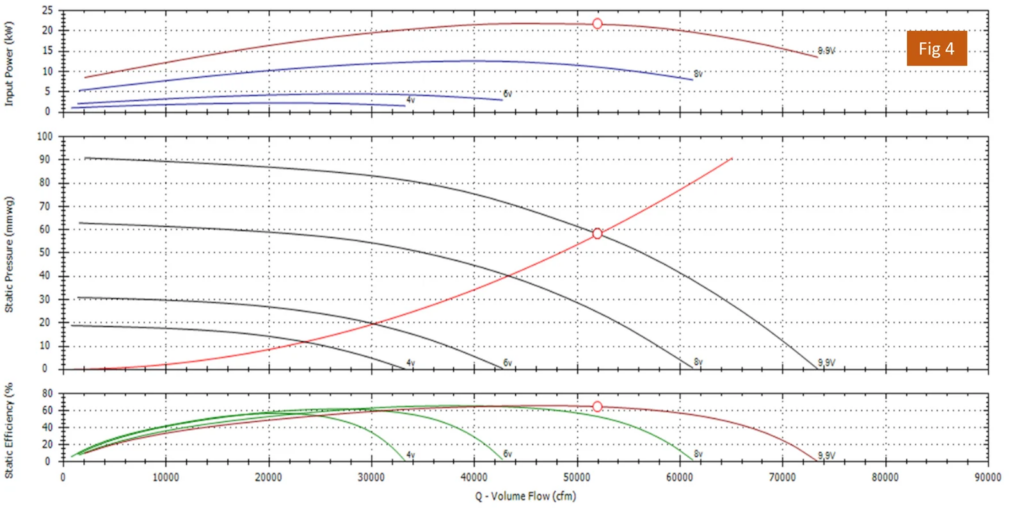

Performance Curve of EC Fan

It can hence be inferred that the power consumed by a conventional DIDW fan is less than the EC fan by about 24%.

But, it is not wise to apply this as a golden rule and conclude that EC fans are less efficient. If the given / required parameter (Flow and Pressure) changes, the scenario will also change. There are many instances wherein the EC fans are much efficient than the conventional fans.

Conclusion

Since the potential for saving energy varies from situation to situation. Converting the conventional fan to EC fan cannot be seen as a “One Stop Solution”. “What to do where” is the key for success and hence a detailed technical analysis will help in identifying the right solution.