Energy efficiency isn’t just a buzzword—it’s the cornerstone of industrial decarbonization efforts. Yet despite significant technological advances and numerous incentive programs, several persistent myths continue to hold back the full adoption of energy-efficient design strategies by HVAC/R equipment manufacturers. Today, we dismantle these myths to reveal the truth and highlight what OEMs need to know.

Table of Contents

- Introduction

- Energy Efficiency’s Role in Industrial Decarbonization

- The 5 Myths

- Myth 1: Component-Level Efficiency Automatically Translates to System-Level Efficiency

- Myth 2: Energy Efficiency Design Improvements Necessarily Increase Manufacturing Costs

- Myth 3: Designing for Maintenance Access Compromises Efficiency

- Myth 4: Standard Design Software Always Optimizes Energy Performance

- Myth 5: Control System Design Is Secondary to Mechanical Component Selection

- Practical Recommendations

- Adopt an Integrated Design Approach

- Implement Advanced Modeling and Testing Protocols

- Design for Serviceability Without Compromising Efficiency

- Optimize Control Logic During the Design Phase

- Consider Lifecycle Value in Component Selection

- The Bottom Line

- Summary of Debunked Myths and Key Takeaways

- Dual Benefits: Competitive Advantage and Environmental Impact

- Contact Us

Energy Efficiency’s Role in Industrial Decarbonization

In the industrial sector—which accounts for approximately 24% of global CO₂ emissions—HVAC/R systems typically represent 30-40% of a facility’s total energy consumption, making them prime targets for optimization. As equipment manufacturers, OEMs hold significant influence over the energy efficiency landscape through their design decisions.

From a technical perspective, improving efficiency in equipment design requires optimizing thermodynamic processes by reducing entropy generation, enhancing heat transfer coefficients, minimizing pressure drops, and strategically selecting components that work synergistically. The core challenge lies not in individual component selection but in system integration—ensuring that compressors, heat exchangers, expansion devices, and controls work together optimally across all operating conditions.

For OEMs, designing energy-efficient equipment isn’t just about meeting regulatory requirements—it’s about creating competitive advantage. As energy costs continue to rise and sustainability becomes a key purchasing criterion, equipment that delivers superior efficiency commands premium pricing and builds brand reputation. The most successful manufacturers recognize that efficiency must be designed in from the beginning, not added as an afterthought. At Asset-Eyes Infomatics, we’ve seen how this proactive approach to efficiency design gives our HVAC/R manufacturing partners a significant edge in increasingly competitive markets.

Myth 1: Component-Level Efficiency Automatically Translates to System-Level Efficiency

Many design engineers believe that selecting the most efficient individual components—high-efficiency compressors, premium heat exchangers, and advanced expansion devices—automatically results in an optimally efficient system.

Reality Check: Component-level efficiency ratings provide an incomplete picture of system performance. The interactions between components often matter more than their individual specifications. For example, a high-efficiency compressor paired with an undersized condenser will result in higher discharge pressures and reduced overall efficiency. Similarly, a premium expansion valve without proper control logic may cause hunting, reducing system COP.

Effective design requires system-level thinking and analysis of component interactions across the entire operating envelope. This includes part-load performance, which often dominates energy consumption in real-world applications. The most energy-efficient designs optimize component matching, refrigerant circuit design, and control logic to ensure that the entire system operates at peak efficiency during typical usage patterns, not just at full load or standard rating conditions.

Myth 2: Energy Efficiency Design Improvements Necessarily Increase Manufacturing Costs

A persistent belief among product development teams is that designing for energy efficiency invariably drives up manufacturing costs, making products less competitive in price-sensitive markets.

Reality Check: While some efficiency improvements do require premium components or additional manufacturing steps, many efficiency-enhancing design strategies actually reduce costs or remain cost-neutral. For example, optimizing refrigerant circuit design often requires more engineering time but not necessarily more expensive materials. Similarly, improving airflow paths through computational fluid dynamics (CFD) analysis can enhance heat exchanger performance without increasing material costs.

Advanced manufacturing techniques like selective brazing, precision tube expansion, and optimized fin designs can simultaneously improve thermal performance and reduce material usage. Furthermore, a growing body of research indicates that designing for energy efficiency often aligns with designing for manufacturing efficiency—both approaches emphasize material optimization, reduced complexity, and system integration.

When lifecycle value is considered, energy-efficient designs typically command premium pricing that more than offsets any incremental manufacturing costs. According to the U.S. Department of Energy’s Better Buildings initiative, purchasers of commercial HVAC equipment are increasingly evaluating total cost of ownership rather than focusing solely on initial purchase price, particularly for larger systems where energy costs represent a significant portion of lifecycle expenses.

Myth 3: Designing for Maintenance Access Compromises Efficiency

Many design engineers believe that creating equipment with excellent serviceability necessitates compromises in efficiency—perhaps through larger cabinets with more internal air leakage, additional access panels that create thermal bridges, or component arrangements that prioritize access over optimal refrigerant flow.

Reality Check: Serviceability and efficiency are not inherently opposing goals. In fact, equipment designed with maintenance in mind often maintains its efficiency better over time. The key lies in thoughtful design that considers both objectives simultaneously rather than treating them as trade-offs.

For example, strategic placement of service ports for refrigerant monitoring doesn’t require compromising the refrigerant circuit design. Similarly, quick-connect electrical terminals for replaceable components don’t impact energy performance but dramatically improve serviceability. Modular designs that allow targeted component replacement without system-wide disassembly can maintain both efficiency and serviceability.

Moreover, designing for condition monitoring—incorporating pressure taps, temperature sensor wells, and diagnostic ports—enables preventive maintenance that preserves efficiency throughout the equipment’s lifecycle. The most advanced designs now include self-diagnostic capabilities that identify efficiency degradation before it significantly impacts performance, allowing for targeted maintenance interventions.

Myth 4: Standard Design Software Always Optimizes Energy Performance

There’s a widespread assumption that using industry-standard design software automatically results in energy-optimized equipment designs. Many engineering teams rely heavily on these tools without questioning their underlying assumptions or limitations.

Reality Check: While design software provides valuable guidance, it often relies on simplified models and standardized assumptions that may not reflect real-world operating conditions. Most programs optimize for standard rating conditions rather than for the variable loads and ambient conditions equipment experiences in actual applications.

Furthermore, many software packages don’t adequately model transient behaviors like defrost cycles, startup dynamics, or capacity modulation strategies—all of which significantly impact real-world energy consumption. The most energy-efficient designs emerge when engineers use software as a starting point but validate and refine designs through physical prototyping, laboratory testing across diverse conditions, and field monitoring of actual installations.

Advanced manufacturers supplement standard software with computational fluid dynamics (CFD), finite element analysis (FEA), and custom simulation tools that more accurately predict performance across the entire operating envelope. This multi-tool approach, combined with empirical testing, leads to designs that outperform those developed using standard software alone.

Myth 5: Control System Design Is Secondary to Mechanical Component Selection

Many equipment designers focus primarily on mechanical component selection and refrigerant circuit design, treating control systems as an afterthought to be addressed later in the development process.

Reality Check: In modern HVAC/R equipment, control logic often influences energy efficiency as much as—or more than—mechanical component selection. Advanced control strategies can optimize system operation across varying conditions, manage capacity modulation to maximize part-load efficiency, and minimize energy-intensive transitions like defrost cycles or compressor cycling.

The integration of variable speed drives (VSDs) offers a prime example. Simply incorporating a VSD without optimizing the control logic rarely delivers the full efficiency potential. The most effective implementations pair VSDs with sophisticated algorithms that continuously adjust speeds based on load requirements, system pressures, and ambient conditions. These algorithms must be developed and refined during the core design phase, not added as an afterthought.

Leading manufacturers now approach control system design as a co-equal priority with mechanical design, involving controls engineers from the earliest concept stages. This integrated approach enables innovations like predictive control algorithms that anticipate load changes, adaptive tuning that optimizes parameters based on actual performance data, and fault-tolerant operation that maintains efficiency even when components begin to degrade.

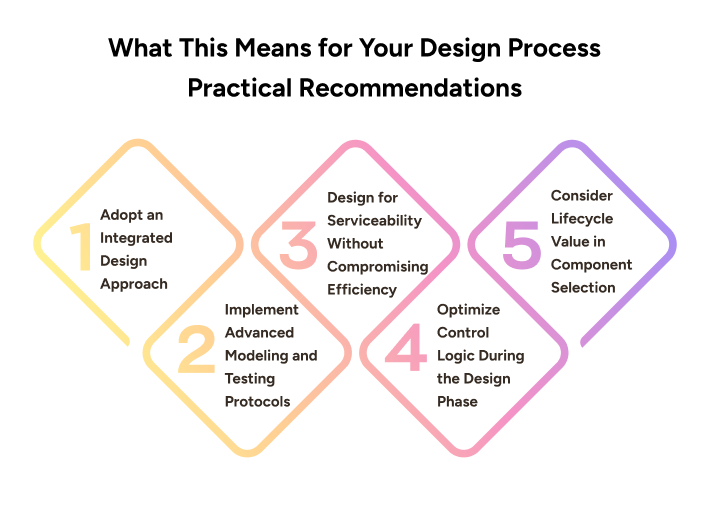

What This Means for Your Design Process: Practical Recommendations

Based on these insights, here are actionable recommendations for HVAC/R equipment manufacturers:

1.Adopt an Integrated Design Approach

- Assemble cross-functional teams that include mechanical, electrical, controls, and manufacturing engineers from the project outset

- Develop system-level performance specifications before selecting individual components

- Use quality function deployment (QFD) to translate customer requirements into technical specifications

- Implement concurrent engineering practices that consider efficiency, manufacturability, and serviceability simultaneously

- Establish clear energy performance metrics that go beyond standard rating conditions

2.Implement Advanced Modeling and Testing Protocols

- Supplement standard design software with advanced simulation tools for more accurate performance prediction

- Create digital twins of equipment designs to analyze performance across the entire operating envelope

- Develop testing protocols that evaluate efficiency under dynamic conditions, not just steady-state operation

- Implement design of experiments (DOE) methodologies to efficiently optimize multiple design parameters

- Validate designs through accelerated life testing that captures long-term efficiency impacts

3.Design for Serviceability Without Compromising Efficiency

- Create modular designs that allow component replacement without compromising system integrity–a capability Asset-Eyes Infomatics enhances through specialized HVAC/R-focused CAD/CAE services

- Incorporate non-invasive diagnostic capabilities that don’t require system disassembly

- Design refrigerant circuits with service valves and access ports at strategic locations

- Develop clear service documentation and procedures during the design phase, not after—Asset-Eyes Infomatics specializes in creating comprehensive technical documentation that balances detail with usability

- Consider the technician experience as a key design criterion alongside efficiency metrics

4.Optimize Control Logic During the Design Phase

- Involve controls engineers from the earliest concept development stages

- Develop control algorithms based on system-level efficiency objectives, not just component protection

- Implement model-based control development using hardware-in-the-loop testing

- Design controls that optimize performance across the most common operating conditions

- Create adaptive control strategies that maintain efficiency as components age or conditions change

5.Consider Lifecycle Value in Component Selection

- Evaluate components based on lifetime energy consumption, not just purchase price

- Analyze the reliability implications of component choices on long-term efficiency

- Consider the impact of component selection on manufacturing complexity and quality control

- Develop clear ROI models that demonstrate the value of efficiency-enhancing design features

- Create tiered product offerings that allow customers to select their optimal efficiency/cost balance

The Bottom Line

The evidence is clear: when it comes to HVAC/R equipment design, system-level thinking beats component-level selection and thoughtful design can enhance efficiency without increasing costs. Serviceability and efficiency can be complementary goals. Advanced modeling tools deliver superior results, and control system design is fundamental to energy performance.

By dispelling these myths with evidence-based design practices, HVAC/R equipment manufacturers can develop products that deliver superior energy efficiency while maintaining competitive manufacturing costs. These products not only command premium pricing in the marketplace but also build brand reputation for innovation and sustainability commitment.

For design engineers and engineering managers, the path forward involves breaking down silos between disciplines, investing in advanced design tools and testing capabilities, and approaching energy efficiency as a fundamental design criterion rather than a marketing feature. The manufacturers who embrace these approaches will lead the industry in both profitability and environmental impact.

At Asset-Eyes Infomatics, we partner with HVAC/R OEMs to implement these evidence-based design practices through our specialized design and drafting services. From system-level optimization to detailed component design, our team helps manufacturers navigate efficiency challenges at every stage of product development. Ready to enhance your equipment’s energy efficiency through improved design practices? Contact our team at sales@asset-eyes.com or call us at +91 9840895134 to discuss how we can support your specific design needs!