Table of Contents

- Introduction

- Efficiency and Sustainability

- Energy Efficiency: The New Competitive Edge

- Sustainable Refrigerants: Meeting Environmental Challenges

- Smart Design and Operations

- Smart Technology: Making Chillers Intelligent

- Modular Design: Flexibility Meets Performance

- Maintenance Revolution: From Reactive to Predictive

- Market Applications and Future Outlook

- Industry-Specific Solutions: Specialized Cooling Technology for Specialized Needs

- Looking Ahead: What’s Next for Industrial Chillers

- Conclusion: Navigating the Changing Landscape

Introduction

The industrial cooling landscape is experiencing a significant transformation. Rising energy costs, stricter environmental regulations, and technological advancements are reshaping how industrial chillers, the workhorses of cooling for manufacturing facilities, data centers, and commercial buildings are designed and operated. This evolution isn’t just about making things colder. It’s about creating evaporative cooling system design that are smarter, more efficient, and more sustainable than ever before. The global chillers market is set to grow from $12.08 billion in 2024 to $15.42 billion by 2029, propelled by rapid industrialization, urban growth, and the rising need for energy-efficient cooling technology.

At Asset-Eyes Infomatics, we specialize in HVAC equipment design and CAD drafting services, helping manufacturers navigate these changes and incorporate emerging innovations into their products. As we explore the major trends reshaping industrial chiller design since 2022, you’ll discover how these advancements are creating both challenges and opportunities for equipment manufacturers.

Efficiency and Sustainability

Energy Efficiency: The New Competitive Edge

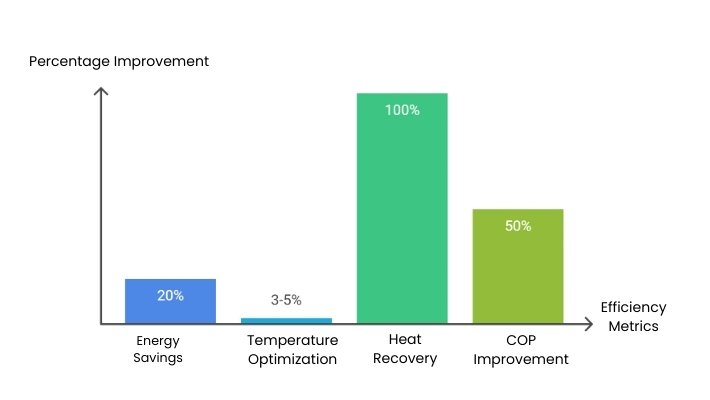

Energy efficiency has shifted from being a desirable feature to becoming a vital competitive advantage. Today’s best in class chillers deliver up to 20% energy savings compared to designs from just a few years ago, a difference that translates directly to lower operating costs and reduced environmental impact.

Advanced Compressor Technologies

Advanced compressor technologies are at the core of modern chiller efficiency.Variable speed compressors automatically adjust their output based on actual cooling technology demand rather than running continuously at full capacity. Think of it like driving a car with adaptive cruise control that perfectly matches your speed to traffic conditions, rather than maintaining a constant speed regardless of the road ahead.

Single screw compressors with integrated refrigerant cooled inverters, like those in Daikin’s MZ Series chillers, exemplify this trend. These systems maintain optimal performance even in extreme conditions up to 55°C increasingly important as climate change brings more frequent temperature extremes. At Asset-Eyes, we’ve helped manufacturers implement these advanced compressor technologies while ensuring designs remain production-friendly and cost-effective.

Temperature Optimization Strategies

Sometimes the simplest changes bring significant benefits. Research shows that raising the chilled water supply temperature by just 2°F can reduce energy consumption by 3-5% in commercial buildings without impacting comfort during mild weather.

Heat recovery systems capture waste heat from cooling technology processes and repurpose it for water or space heating effectively doubling the value derived from energy input. It’s like receiving two machines for the cost of one. Our design team specializes in integrating these recovery systems into new equipment designs, helping manufacturers offer products with compelling ROI stories for end-users.

Performance Metrics That Matter

Modern chillers achieve coefficient of performance (COP) ratings of 6 or higher, meaning they produce 6 kW of cooling for every 1 kW of electricity consumed. This represents nearly double the efficiency of older systems with typical COPs of 3-4, creating a compelling case for equipment upgrades even in facilities with functioning older systems.

Sustainable Refrigerants: Meeting Environmental Challenges

Perhaps no aspect of chiller design is changing more rapidly than refrigerant technology. As regulations phase out traditional refrigerants with high global warming potential (GWP), manufacturers must pivot to more environmentally friendly alternatives without compromising performance.

The New Generation of Refrigerants

Several options are gaining prominence:

- Hydrofluoroolefins (HFOs): These offer nearly zero GWP without compromising system efficiency, making them ideal for industrial applications where environmental impact is a concern.

- Carbon Dioxide (CO2): In high-pressure applications, CO2 delivers excellent efficiency and low operating costs. It’s particularly popular in food processing and cold storage, where its safety profile and performance shine.

- Hydrocarbons: Natural refrigerants such as propane are regaining popularity because of their low environmental impact and high energy efficiency. While they require additional safety measures due to flammability, improved system designs are making them increasingly viable.

- R1234ze: With a GWP of just 7 (compared to thousands for older refrigerants), this option is appearing in high-capacity chillers like the Vertiv Liebert AFC, dramatically reducing climate impact.

Switching to these new refrigerants demands careful redesign of system components, pressure ratings, and safety features. At Asset-Eyes, we help manufacturers navigate these complex transitions, ensuring designs meet both regulatory requirements and performance expectations while remaining cost-effective to produce.

Navigating the Regulatory Landscape

The EU F-Gas Regulation and similar global initiatives are speeding up the shift toward sustainable refrigerants. Forward thinking manufacturers are designing chillers that not only comply with current regulations but anticipate future restrictions.

Taking this proactive approach helps businesses prevent expensive retrofits in the future. It’s like building a house that already meets future building codes, a smart investment that pays dividends over time. Our design team specializes in creating systems that balance environmental requirements with manufacturing realities, ensuring your products remain compliant across global markets.

Looking to ensure your chiller designs meet both efficiency targets and regulatory requirements? Contact Asset-Eyes Infomatics at sales@asset-eyes.com to discuss how our specialized HVAC/R design services can help your team navigate these complex challenges while maintaining manufacturability and cost targets.

Smart Design and Operations of Cooling Technology

Smart Technology: Making Chillers Intelligent

If traditional chillers were the workhorses of industrial cooling technology, today’s smart chillers are precision engineered racehorses responsive, adaptable, and equipped with intelligence that transforms how they perform.

Real-time Monitoring and Control

Modern chillers are equipped with sensors and connectivity features that allow continuous monitoring of key parameters such as temperature, pressure, and energy consumption. Operators can remotely access this information, allowing them to make adjustments anytime and from anywhere.

User-friendly interfaces, including intuitive touch displays, make these sophisticated systems accessible to operators with varying levels of technical expertise. It’s like having a smartphone instead of a 1990s flip phone more powerful but also easier to use. Integrating these intelligent features requires careful consideration of both software and hardware components. Asset-Eyes helps manufacturers incorporate these technologies while maintaining production efficiency and reliability.

The Power of Data Analytics and AI

The real magic happens when chillers leverage data analytics and artificial intelligence to optimize performance. These systems recognize patterns and trends that manual detection would miss, enabling predictive maintenance and optimizing performance.

Energy Management Systems (EMS) now use AI algorithms to predict consumption patterns and adjust chiller operations accordingly. This proactive approach maintains optimal energy use without requiring constant human oversight like having an efficiency expert continuously fine-tuning your system.

Seamless Building Integration

Modern chillers integrate smoothly with broader building management systems, enabling coordinated operation of all HVAC components. This holistic approach optimizes overall building performance rather than focusing on individual systems in isolation.

The Vertiv Liebert iCOM control system illustrates this trend by managing the chiller and communicating with the building management system. This integration enables comprehensive monitoring and coordinated responses to changing conditions Like having every musician in an orchestra play from the same sheet of music.

Modular Design: Flexibility Meets Performance

One size fits all approaches are giving way to modular, scalable designs that can adapt to changing needs and space constraints, a trend that’s reshaping how manufacturers approach equipment design.

Flexible Capacity When You Need It

Modular chiller systems enable businesses to add or remove units as required, making them well-suited for operations with varying cooling technology demands. This approach enables precise matching of cooling capacity to actual needs, avoiding the energy waste associated with oversized systems.

It also provides a pathway for incremental expansion as cooling requirements grow, eliminating the need for major capital investments in anticipation of future needs. Think of it like adding extra cars to a train rather than building an entirely new railway. Asset-Eyes specializes in designing modular systems that optimize performance, manufacturability, and ease of installation ensuring your products stand out in competitive bid situations.

Making the Most of Limited Space

Space efficiency has become a critical consideration in chiller design, particularly in urban environments where real estate comes at a premium. Modern chillers feature compact footprints that maximize cooling capacity per square foot of installation space.

Space efficiency frees up valuable facility space for other equipment or future expansion, a compelling selling point for facilities with limited mechanical room space.

Adapting to Diverse Environments

Today’s chillers operate effectively across a wide range of environmental conditions, making them suitable for global deployment. The best systems offer operating ranges from -25°C to +56°C external ambient temperature, providing exceptional versatility in our changing climate.

This adaptability is particularly important for manufacturers selling into multiple global markets with varying climate conditions. At Asset-Eyes, we help manufacturers design systems that perform reliably across diverse operating environments while maintaining manufacturing consistency and cost efficiency.

Maintenance Revolution: From Reactive to Predictive Cooling Technology

The way we maintain industrial chillers is undergoing a fundamental shift, moving from reactive repairs to predictive maintenance that prevents problems before they occur.

The Predictive Advantage

Predictive maintenance utilizes data analytics and machine learning to detect potential problems before they lead to breakdowns. This approach offers several significant benefits:

- Decreased downtime by prioritizing scheduled maintenance over emergency repairs.

- Extended equipment lifespan through early intervention

- Reduced maintenance expenses by fixing minor issues before they become major problems.

- Optimized maintenance scheduling based on actual equipment condition

It’s like having a doctor who can predict health problems months in advance rather than treating symptoms after you’re already sick. Predictive maintenance capabilities must be designed into the system from the beginning. We’ve helped HVAC/R manufacturers incorporate these features into their designs, resulting in products that offer significant value-added benefits to end users.

Fluid Management for Long-Term Performance

Effective fluid management has become a key factor in ensuring chiller efficiency and reliability. Regular testing and treatment prevent corrosion, scaling, and biological growth that can degrade performance and damage system components.

Equipment designed with maintenance in mind including easy access to fluid systems, clear sight glasses, and integrated filtration commands premium pricing and builds brand reputation for reliability. These simple design considerations can significantly extend equipment life and preserve energy efficiency over time.

Comprehensive Monitoring for Peace of Mind

Advanced monitoring technologies now track everything from refrigerant levels to electrical connections, providing comprehensive oversight of chiller operation. The data collected creates a historical record that helps identify long-term trends and inform future equipment decisions.

Ready to implement these advancements in your chiller designs?

Asset-Eyes Infomatics specializes in HVAC/R equipment design and drafting services that incorporate these innovations while ensuring manufacturability. Schedule a consultation today at +91 9840895134 to see how we can enhance your product development process and help you bring more competitive products to market faster.

Market Applications and Future Outlook – Cooling Technology

Industry-Specific Solutions: Specialized Cooling for Specialized Needs – Cooling Technology

As cooling requirements become more diverse and demanding, chiller manufacturers are developing specialized solutions for specific industries and applications creating opportunities for product differentiation and premium positioning.

Cooling the AI Revolution

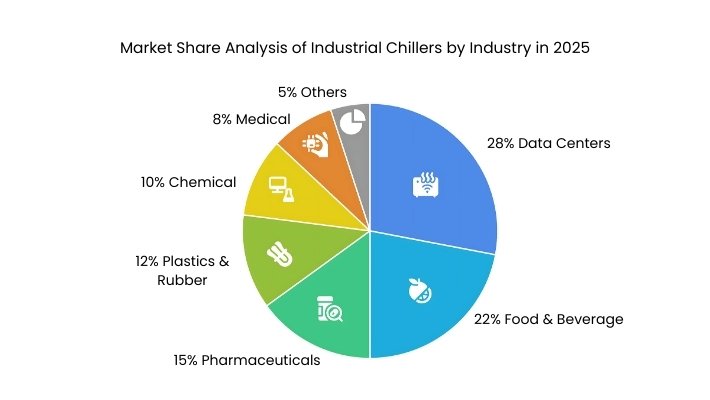

The explosive growth of data centers, particularly those supporting AI and machine learning, has created unprecedented cooling challenges. These facilities generate intense heat loads that require specialized cooling technology solutions.

High-capacity chillers designed specifically for data centers offer compatibility with liquid cooling technology for high density server racks, capacity to handle extreme heat loads (up to 2.2MW in a single unit), and compact footprints to maximize valuable data center space. An industry expert noted, “The market increasingly requires high-density, AI-ready chillers built for liquid cooling to design tomorrow’s data centers with future needs in mind.”

Food and Beverage: Precision Cooling Technology for Quality and Safety

Food and beverage processing represents one of the fastest-growing segments for industrial chillers. This growth is driven by increasing consumer demand for processed foods, stringent regulatory standards, expansion of cold chain logistics, and rising demand for premium products that require precise temperature control.

Chillers for this sector emphasize reliability, precision, and compliance with food safety standards essential features in an industry where temperature fluctuations can compromise product quality and safety.

Commercial Buildings: Balancing Performance and Integration

Commercial buildings represent a significant market for industrial chillers, with a focus on energy efficiency, reliability, and integration with building management systems.

The 300-700 kW capacity segment is growing fastest in this sector, offering a balance between performance and space optimization. These systems typically feature variable speed technology to match cooling output to actual demand, heat recovery options, and low-noise designs for urban environments.

Looking Ahead: What’s Next for Industrial Chillers For Cooling Technology

As we look beyond 2025, several emerging trends promise to further transform industrial chiller technology:

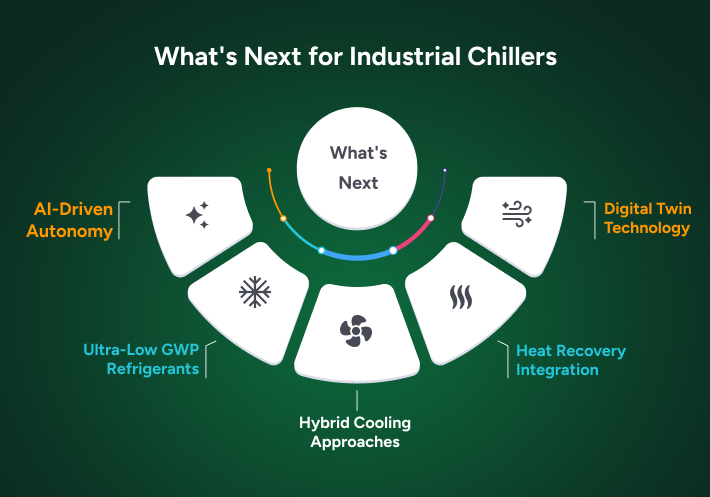

1.AI-Driven Autonomy

Further integration of artificial intelligence will enable increasingly autonomous chiller operation, with self optimizing systems that continuously adapt to changing conditions without human intervention. These systems will not just respond to current conditions but anticipate future needs based on weather forecasts, occupancy patterns, and other predictive factors.

2.Ultra-Low GWP Refrigerants

The quest for environmentally friendly refrigerants continues, with ongoing refinement of options with minimal environmental impact. This includes both new synthetic options and broader adoption of natural refrigerants, with a focus on balancing performance, safety, and sustainability.

3.Hybrid Cooling Approaches

Expect increased adoption of hybrid systems that combine traditional mechanical cooling with alternative approaches such as Evaporative cooling system design, geothermal exchange, or absorption technologies. These combined systems will offer the best of both worlds reliable performance with reduced environmental impact.

4.Heat Recovery Integration

Greater emphasis on heat recovery and waste heat utilization will transform how we think about chillers not just as cooling equipment but as part of integrated energy systems that maximize the value of every input. This shift aligns with broader sustainability goals and offers significant operational cost benefits.

5.Digital Twin Technology

Expanded use of digital twins virtual replicas of physical systems will enable more precise equipment selection, predictive performance modeling, and optimization. This approach allows engineers to test different scenarios and configurations virtually before implementing changes in the real world.

Conclusion: Navigating the Changing Landscape

The industrial chiller industry stands at a fascinating crossroads. The drive for energy efficiency, the transition to sustainable refrigerants, the growth of smart technologies, and the expansion of data-intensive applications are all converging to create both challenges and opportunities.

For equipment designers and manufacturers, these trends represent both challenges and opportunities. Those who successfully incorporate these innovations into their products will command premium pricing, build brand loyalty, and capture market share in an increasingly competitive landscape.

As we move forward, the focus will increasingly be on total value not just purchase price or even energy efficiency, but the complete package of performance, reliability, adaptability, and environmental impact. The industrial chillers of tomorrow will be smarter, greener, more flexible, and more capable than ever before.

At Asset-Eyes Infomatics, we help HVAC/R manufacturers stay ahead of these trends through specialized design and drafting services. Our team understands both the technical requirements and manufacturing realities of modern chiller design, helping you bring innovative products to market faster and more cost-effectively.

Contact us today at sales@asset-eyes.com or +91 9840895134 to discuss how we can support your equipment design needs and contribute to your continued success in this rapidly evolving industry.