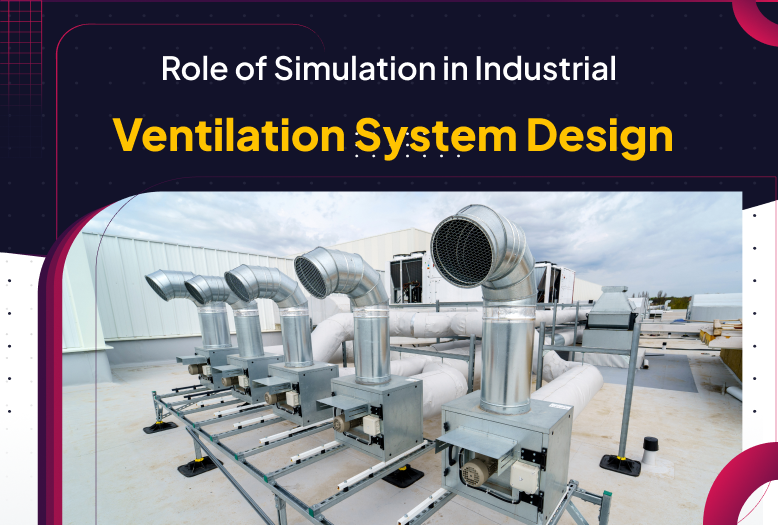

Proper ventilation is one of the most important aspects of creating a safe and efficient industrial facility. Whether it’s a factory, warehouse, or chemical plant, the right airflow helps protect worker health, remove hazardous gases, control temperature, and enhance overall comfort. However, Industrial Ventilation System Design can be challenging, especially in large and complex buildings.

That’s why simulation technology is now widely used by engineers and facility designers. It allows them to create a virtual model of the building and test how air will flow, where heat will accumulate, and how pollutants might spread all before any physical equipment is installed.

In this blog, we’ll explore what simulation is, why it’s important, and how it enhances Industrial Ventilation System Design for better safety and efficiency.

Understanding Industrial Ventilation

industrial ventilation systems design refers to the mechanical and natural methods used to circulate air, remove airborne contaminants, and regulate temperature within industrial facilities. These systems are crucial in environments such as manufacturing plants, chemical facilities, refineries, data centers, and warehouses, where heat, fumes, and particulate matter can threaten both worker safety and equipment efficiency.

There are typically two categories of industrial ventilation:

- Dilution Ventilation – Delivers fresh air into the space to lower contaminant levels and assist in their removal.

- Local Exhaust Ventilation – Removes contaminants at the point of origin, preventing them from dispersing into the surrounding air.

Each industrial facility has unique requirements, making proper system design vital. Design errors can result in inadequate airflow, energy inefficiency, non-compliance with regulations, or hazardous working environments.

Comparison of Dilution Ventilation Vs Local Exhaust Ventilation

| Category | Dilution Ventilation | Local Exhaust Ventilation |

|---|---|---|

| How it works | Mixes fresh air with dirty air to reduce harmful substances | Captures and removes harmful substances directly at the source |

| Cost | Lower setup and equipment cost | Higher setup and equipment cost |

| Maintenance | Needs less maintenance | Needs regular cleaning and checking |

| Best for | Low-risk chemicals, large open areas, or moving sources | Highly dangerous chemicals and fixed sources like machines or workstations |

| Air needed | Needs a lot of fresh air which may need heating or cooling | Needs less fresh air, so saves on heating or cooling costs |

| Effectiveness | Works well only for small amounts of low-risk chemicals | Works well for dust, metal fumes, gases, and vapours |

| Energy use | Uses more energy due to high air volume | Uses less energy |

| Limitations | Doesn’t fully remove harmful air, not good for dust or strong fumes | Expensive and complex to set up, not ideal for large open or moving sources |

The Challenges of Traditional Ventilation Design

Traditional design ventilation systems industrial is often based on standard formulas, physical testing, and best-practice layouts. While this may work in simple settings, it often falls short in complex industrial environments where:

- Equipment layouts are irregular or congested.

- Multiple heat or contaminant sources exist.

- External factors such as weather and seasonal changes can impact indoor air quality.

- Energy efficiency and cost control are top priorities.

In such cases, guesswork or trial-and-error methods can result in costly inefficiencies and unsafe working conditions. This is where simulation-based design becomes a powerful solution.

What is Simulation in Ventilation Design?

Simulation in design of ventilation systems in industries involves using software tools especially Computational Fluid Dynamics (CFD) to create a virtual model of the industrial space. These digital environments replicate the physical layout, air inlets and outlets, heat sources, machinery, and airflow patterns.

Through simulation, engineers can:

- Visualize how air moves throughout a facility.

- Identify dead zones, hot spots, or areas with insufficient ventilation.

- Test various design scenarios before implementation.

- Optimize the location and sizing of fans, ducts design, and filters.

- Forecast the behavior of contaminants or heat under different conditions.

This predictive ability reduces risk, improves system performance, and supports compliance with health and safety standards.

Key Benefits of Simulation in Industrial Ventilation System Design

Simulation brings numerous advantages to the industrial design process. Below are some of the most impactful:

1. Enhanced Design Accuracy

Simulations provide detailed visualizations and data-driven predictions of airflow and temperature distributions. This leads to more precise and effective design decisions.

2. Improved Air Quality and Worker Safety

By identifying potential problem areas (such as stagnant air or high contaminant zones), simulation ensures the system design effectively removes harmful particles and gases, protecting employee health.

3. Increased Energy Efficiency

Well-designed systems reduce over-ventilation or unnecessary fan usage. Simulation enables engineers to balance performance with energy consumption, resulting in lower utility costs and a reduced carbon footprint.

4. Cost Savings on Implementation

Simulation reduces reliance on trial and error methods and physical prototypes, leading to significant time and cost savings during the design and installation process.

5. Regulatory Compliance

Simulation tools can validate that the final design complies with standards such as OSHA, ASHRAE, or ISO for ventilation performance and indoor air quality.

6. Support for Complex Environments

For facilities with multiple floors, high ceilings, or enclosed workspaces, simulation allows designers to tailor systems to suit highly specific airflow and contaminant removal needs.

Common Simulation Tools for Industrial Ventilation System Design

Professionals use a variety of tools to simulate airflow and ventilation behavior. Some of the most common include:

a. Computational Fluid Dynamics (CFD)

CFD software is the cornerstone of ventilation simulation. It uses advanced mathematical models to predict fluid (air) flow behavior in complex environments.

Popular CFD software:

- ANSYS Fluent

- Autodesk CFD

- SimScale

- SolidWorks Flow Simulation

b. Energy Modeling Software

These tools evaluate the impact of ventilation on the building’s overall energy use and performance.

Examples include:

- IES VE (Integrated Environmental Solutions)

- EnergyPlus

- Trane TRACE 700

c. Building Information Modeling (BIM)

BIM software integrates industrial ventilation systems design into full 3D building models, enhancing collaboration between architects, engineers, and construction teams.

Popular BIM platforms:

- Autodesk Revit MEP

- AutoCAD MEP

Simulation in the Ventilation Design Process: Step by Step

Let’s walk through how simulation fits into a standard industrial ventilation system design workflow.

Step 1: Data Collection

The process begins with collecting detailed data:

- Building layout and structure

- Heat and contaminant sources

- Air quality targets and regulations

- Environmental and process-specific factors

Step 2: 3D Modeling

Engineers create a digital replica of the industrial space. Ducts, fans, filters, machinery, and vents are added based on real-world specifications.

Step 3: Scenario Simulation

Different environmental and operating conditions are tested:

- Hot and cold seasons

- High-load vs. low-load production

- Emergency shutdowns or fire incidents

Step 4: System Optimization

Simulation results help refine the design. Engineers can adjust:

- Airflow paths

- Fan placements and sizes

- Ventilation rates

- Heat recovery systems

Step 5: Design Validation and Documentation

Once optimized, the design is validated against benchmarks and regulations. All documentation is prepared for stakeholder approval and system installation.

Real-World Applications of Simulation

Automotive Manufacturing: In automotive plants, welding areas generate large amounts of heat and fumes. CFD simulations help position exhaust vents precisely to maintain air quality and reduce worker exposure to harmful gases.

Pharmaceutical Production: Cleanrooms in pharmaceutical plants must maintain strict control over air cleanliness and temperature. Simulations help ensure laminar flow and prevent cross-contamination.

Food and Beverage Facilities: Simulations are used to maintain required humidity levels, prevent mold growth, and ensure hygienic air circulation in processing zones.

Chemical Industries: Handling hazardous materials demands accurate ventilation planning. Simulations help design emergency ventilation for accidental spills or chemical releases.

Simulation for Sustainable and Smart Ventilation

Sustainability is now a top priority in industrial ventilation systems design. Simulation plays a key role in helping facilities achieve their energy efficiency and sustainability goals.

Benefits include:

- Incorporating natural ventilation where possible

- Integrating heat recovery systems

- Optimizing smart controls for dynamic airflow adjustment

- Reducing overall carbon footprint

Advanced simulation models can also interface with IoT devices to enable real-time monitoring and adjustment of design of industrial ventilation systems based on actual facility conditions.

Challenges and Considerations

While simulation tools are powerful, there are some limitations:

- Expertise required: CFD modeling and analysis require trained professionals.

- Software costs: Licensing fees for high-end tools can be expensive.

- Data sensitivity: Simulation accuracy depends heavily on quality of input data.

- Ongoing updates: Designs may need regular updates to reflect process changes or facility expansion.

Despite these challenges, the return on investment (ROI) from simulation often outweighs the initial costs especially in large or high-risk industrial environments.

The Future of Simulation in Industrial Ventilation System Design

As technology advances, simulation will continue to evolve. Here are a few exciting trends:

- AI-driven simulations: Use machine learning to automatically optimize designs based on thousands of test cases.

- Digital twins: Real-time, virtual replicas of physical systems for continuous monitoring and adjustment.

- Cloud-based platforms: Allow collaboration across teams and locations with access to high-performance computing resources.

- Virtual reality (VR) integration: Enables designers to experience airflow behavior in immersive 3D environments before construction.

These innovations will further improve the speed, accuracy, and reliability of industrial ventilation design.

Looking For Expert Help with Industrial Ventilation Design?

At Asset-Eyes, we specialize in industrial ventilation system design using advanced simulation tools to ensure optimal airflow, safety, and regulatory compliance. Our team delivers custom, cost-effective ventilation solutions backed by extensive experience in HVAC equipment design, SolidWorks design, and CAD drafting service.

As part of our comprehensive mechanical design and simulation services, we offer:

- Complete cad drafting and design services for mechanical systems

- HVAC CAD drafting and system layout planning

- SolidWorks design for equipment and ductwork

- 2D drafting in SolidWorks for precise engineering documentation

- Detailed general assembly drawings

- Professional CAD drawings services tailored to your industry

Our solutions support industries such as manufacturing, pharmaceuticals, automotive and more.

Whether you need support for HVAC system design or detailed CAD drafting, Asset-Eyes has the tools and expertise to deliver.

Contact Asset-Eyes today to discuss your project needs and get started with a smarter, simulation-driven design of industrial ventilation systems approach.

Final Thoughts

Simulation is changing the way industrial ventilation system design. It helps engineers see how air moves in a building, fix problems before they happen, and save time and money. Most importantly, it makes sure your workplace is safe, clean, and comfortable.

Whether you are building a new facility or upgrading an old one, using simulation can help you make smart choices. It leads to better airflow, lower energy bills, and happier, healthier workers.

At Asset-Eyes, we use the latest simulation tools to design powerful and efficient industrial ventilation systems engineering design. Our expert team creates solutions that fit your space, your goals, and your budget. If you’re ready to improve air quality and energy savings at your facility, we’re here to help. Contact Asset-Eyes today and let’s build a better, safer future together.