In the world of HVAC/R (Heating, Ventilation, Air Conditioning and Refrigeration) systems, efficiency is paramount. The cooling tower is a vital component that greatly enhances the overall performance of HVAC/R systems. Whether in large commercial buildings, industrial plants, or even district cooling systems, cooling towers help in the critical task of heat dissipation, improving system efficiency, and supporting energy conservation efforts.

At Asset-Eyes, our drafting team specializes in translating cooling tower specifications into precise technical drawings that support broader HVAC/R system designs. By providing detailed and production-ready documentation, we help ensure that the engineered systems perform as intended. This blog explores how cooling towers function, their role in HVAC/R systems, and how accurate drafting contributes to efficient integration and energy performance.

Table of Contents

- What Are Cooling Towers and How Do They Work?

- Drafting Considerations That Drive Cooling Tower Efficiency

- How Cooling Towers Enhance HVAC/R Efficiency

- Environmental Benefits of Cooling Towers

- Maximizing the Efficiency of Your Cooling Tower

1. What Are Cooling Towers and How Do They Operate?

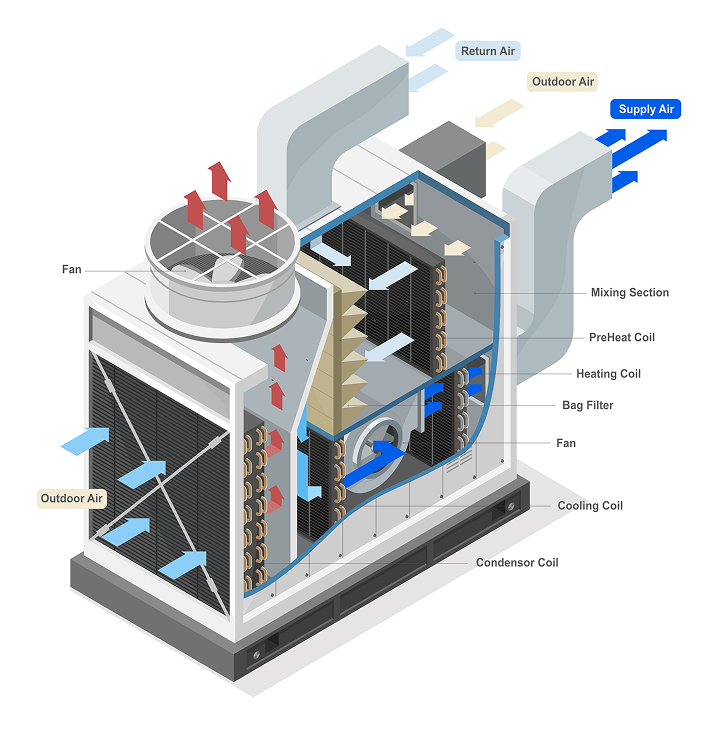

Cooling towers are heat rejection devices designed to cool water or other fluids in HVAC/R systems by transferring heat from the space to be cooled to the atmosphere. They use either natural or mechanical processes to facilitate this heat exchange. Essentially, cooling towers help regulate the temperature of water circulating through the HVAC/R system, preventing the system from overheating.

The Basic Principle of Operation

Cooling towers rely on the principle of evaporative cooling. Here’s a simplified breakdown of the process:

- Hot Water Inflow: Water heated by the system typically from air conditioning units or industrial processes enters the cooling tower.

- Heat Transfer: Warm water flows over fill material typically PVC or polypropylene sheets inside the tower, causing a portion of the water to evaporate.

- Cooling Airflow: Simultaneously, air is sucked into the cooling tower, either naturally or via fans, which accelerates the evaporation process.

- Cooled Water Outflow: The cooled water is then recirculated back into the system to absorb more heat, and the process repeats.

Through this efficient heat exchange process. Cooling towers lower the temperature of the circulating water, improving the overall cooling capacity of the system. At Asset-Eyes, our detailed drafting support ensures that thermal performance requirements specified by engineers are accurately translated into production-ready documentation. Helping clients implement cooling tower designs as intended for optimal energy efficiency.

Types of Cooling Towers

When designing HVAC/R systems, selecting the right type of cooling tower is crucial for system performance. Asset-Eyes offers comprehensive CAD drafting services for a wide range of cooling tower configurations:

Natural Draft Towers: These rely on the natural buoyancy of warm air to create airflow through the tower, requiring no mechanical assistance but demanding precise geometric design for optimal performance.

Mechanical Draft Towers: These use fans to force or induce air movement, offering more control over cooling performance but requiring careful electrical sizing calculations for energy efficiency.

Crossflow Towers: Moreover in these systems, air flows horizontally across the falling water, requiring specialized water distribution design to ensure even coverage.

2. Drafting Considerations That Drive Cooling Towers Efficiency

Airflow Optimization Begins with Clear Drafting

Effective airflow is crucial for the optimal performance of any cooling tower. Asset-Eyes supports airflow optimization by:

- Creating detailed 2D/3D drawings that reflect strategic component placement

- Illustrating airflow paths to reduce resistance and recirculation

- Drafting fan and louver layouts based on client specifications

- Highlighting prevailing wind considerations in tower placement and enclosure designs.

Our background in industrial ventilation system documentation ensures that airflow geometry is clearly visualized. And as well easily referenced across engineering and production teams.

Water Distribution Clarity Drives Consistency

Uneven water distribution can significantly impair a cooling tower’s efficiency. Our drafting services help OEMs and fabricators achieve reliable operation by providing:

- Precise nozzle placement and spray system drawings

- Fill material coverage visualization to reduce dry zones

- BOM generation for all distribution components

- Annotations that minimize drift loss and water waste

Asset-Eyes ensures that water distribution systems are not only functional on paper but easy to manufacture and assemble in practice.

Material Specification Support for Long-Term Reliability

Cooling towers are exposed to moisture, chemical attack, and temperature extremes. Choosing the right materials is essential, and so is documenting those choices correctly. Asset-Eyes helps by:

- Including client-selected materials in detailed CAD documentation

- Clearly annotating corrosion- and UV-resistant material usage

- Identifying high-temperature areas that require special attention

- Supporting the structural drafting needs of load-bearing elements

By embedding accurate material specifications directly into the drawings, we help prevent miscommunication, rework, and costly downtime in the manufacturing phase.

3. How Cooling Towers Enhance HVAC/R Efficiency

Improved Heat Dissipation

One of the primary reasons cooling towers are so critical to HVAC/R systems is their ability to dissipate heat quickly and effectively. In any system, whether it’s air conditioning or industrial cooling, heat buildup can significantly reduce the system’s efficiency. Cooling towers facilitate continuous heat dissipation, ensuring that the system operates at its optimal temperature and efficiency.

By lowering the temperature of the cooling water. Cooling towers prevent the system from becoming overloaded and ensure steady operation. Thereby reducing wear and tear on the system components.

At Asset-Eyes, we support OEMs by translating their thermal and mechanical specifications into precise technical drawings that reflect optimal heat dissipation goals for various load conditions. Our CAD drafting services in SolidWorks ensure that complex heat exchange geometries are accurately represented for seamless integration into manufacturing workflows.

Energy Conservation

Therefore, Efficient cooling is a direct contributor to energy conservation in HVAC/R systems which is always a plus for everyone. Cooling towers are energy-efficient compared to other forms of cooling, such as air-cooled condensers. While air-cooled systems rely on large fans to cool the air, cooling towers use a combination of water evaporation and airflow to achieve more effective heat transfer with less energy expenditure. This can lead to substantial energy savings, especially in large-scale HVAC/R operations.

In fact, cooling towers can improve the overall efficiency of an HVAC/R system by reducing the load on compressors, which are typically the largest consumers of energy in air conditioning systems. By maintaining lower operating temperatures, cooling towers help the HVAC/R system run more efficiently and consume less power.

Asset-Eyes’ electrical engineering services include precise sizing calculations for cooling tower components, ensuring that pumps, fans, and control systems are optimally designed for energy efficiency without sacrificing performance. Our electrical design drafting services translate concepts into precise schematics that provide clear implementation guidance for manufacturing teams.

Extended Equipment Lifespan

By maintaining the ideal operating temperature, cooling towers also help to extend the lifespan of HVAC/R equipment. When systems run at higher temperatures due to insufficient heat dissipation, components like compressors and coils can wear out faster. Requiring more frequent maintenance and replacements, burning unnecessary holes in your clients’ pockets. Cooling towers can help prevent such issues by effectively managing the temperature and improving the longevity of the system while reducing the need for costly repairs or replacements.

Through our detailed mechanical design documentation and simulation-ready models, Asset-Eyes helps OEMs develop cooling tower systems that maintain optimal operating conditions, significantly extending equipment service life. Our collaborative engineering approach ensures that electrical systems work in harmony with all other aspects of your HVAC/R design, preventing premature component failure due to thermal stress.

Reduced Operational Costs

Efficient cooling directly translates into reduced operational costs. Since cooling towers lower the energy consumption of HVAC/R systems, they help reduce electricity costs, which can account for a significant portion of operational expenses in large buildings or industrial plants. By maintaining consistent temperatures and preventing unnecessary overworking of the system, cooling towers contribute to long-term cost savings.

Regular maintenance of cooling towers is also essential to keep them operating at peak performance, helping to reduce downtime and maximize cost efficiency. Asset-Eyes delivers comprehensive documentation packages that include detailed maintenance protocols, helping system operators maintain optimal performance throughout the equipment lifecycle.

4. Environmental Benefits of Cooling Towers

It’s worth noting that while cooling towers are vital for HVAC/R efficiency, they also offer environmental benefits. By using water evaporation for heat dissipation, cooling towers reduce the need for energy-intensive refrigeration processes.

Moreover, since cooling towers reuse water, they promote water conservation, reducing the environmental impact of water waste. This aspect is particularly important in industries or locations where water is a scarce resource.

5. Maximizing the Efficiency of Your Cooling Tower

Regular Maintenance

While regular inspection and maintenance may seem obvious, they remain one of the most effective ways to ensure cooling towers perform at peak efficiency. Common practices include:

- Cleaning the fill material to eliminate debris and scale buildup

- Checking the water treatment system to ensure proper chemical balance, preventing corrosion or scaling

- Inspecting the fan and pump systems for smooth operation

By keeping the cooling tower in top condition, HVAC/R efficiency will be maintained, and energy consumption kept to a minimum.

Upgrading to High-Efficiency Cooling Towers

Advancements in cooling tower technology have led to the development of high-efficiency systems that offer improved performance. These systems use enhanced materials and better airflow designs to achieve higher cooling efficiency, making them ideal for modern HVAC/R applications.

For building owners and facility managers looking to maximize their energy savings, upgrading to these more efficient cooling towers can offer substantial long-term benefits.

Our general assembly drawing services ensure precise alignment of all components, supporting smooth manufacturing and installation processes. For OEMs developing next-generation cooling tower systems, our detailed drafting expertise offers a competitive edge by optimizing the clarity of component specifications and improving manufacturability.

Conclusion

Cooling towers play a pivotal role in enhancing the efficiency of HVAC/R systems by improving heat dissipation, conserving energy, and extending the lifespan of equipment. By reducing the overall energy consumption of HVAC/R systems, cooling towers not only help lower operational costs but also contribute to environmental sustainability.

For OEMs aiming to stand out in a competitive market, cooling towers present a strategic opportunity to enhance system performance and energy efficiency. While the design innovation rests with the OEM, Asset-Eyes supports this process by delivering highly accurate technical drawings and documentation that bring those designs to life.

Our detailed CAD drafting services help ensure that your cooling tower components are production-ready aligned with design intent, compliant with industry standards, and easy to integrate into manufacturing workflows.

Elevate Your HVAC/R Projects with Precision Drafting

Contact Asset-Eyes today to learn how our tailored drafting solutions can help you integrate efficient cooling systems into your HVAC/R setup.

📞 +91 9840895134