Have you ever seen a well-planned project descend into chaos due to just one miscommunication? If you’re managing multiple projects simultaneously, you’ve probably experienced that sinking feeling when a seemingly insignificant error creates a domino effect across your entire project portfolio. The reality is that coordinating multiple installations while managing diverse stakeholder expectations can feel like solving a multi-dimensional puzzle and when coordination falters, inefficiencies multiply quickly. The challenges facing operations managers in larger HVAC/R organizations are real and costly. When projects fail to deliver on time or within budget, the ripple effects extend far beyond a single installation. This blog explores the core project delivery efficiency challenges you face and, more importantly, how strategic improvements to project documentation can transform your HVAC 0perations efficiency.

1. Project Delivery Breaks Down – The Core Efficiency Barriers

Resource Allocation Becomes a Complex Puzzle

As your project portfolio expands, coordinating skilled technicians, specialized equipment, and essential materials grows more complex. Each project carries its own timeline and technical requirements, creating a web of interdependencies that operations managers must navigate daily.

The financial impact of inefficient resource utilization accumulates quickly across multiple projects:

- Idle Time Costs: Highly skilled technicians waiting for materials or unclear installation requirements represent direct profit loss

- Redundant Mobilization: Teams dispatched multiple times due to incomplete documentation create unnecessary travel and setup costs

- Equipment Utilization: Specialized equipment sitting unused while scheduling conflicts prevent optimal deployment

These seemingly small inefficiencies compound across a portfolio of simultaneous projects, directly impacting profitability in ways that can undermine even the most profitable contracts.

Communication Breakdowns Create Costly Ripple Effects

When field teams encounter installation challenges due to unclear or incomplete documentation, the consequences extend far beyond a single project. Operations managers find themselves coordinating emergency responses that affect multiple interconnected projects:

- Emergency Redesigns: Last-minute engineering changes required when field conditions don’t match documentation

- Material Substitutions: Finding alternative components when original specifications don’t fit.

- Schedule Adjustments: Cascading delays that affect resource allocation across multiple sites

These communication breakdowns between field teams, engineering departments, and project management create very costly delays. The issue isn’t just the immediate fix, it’s the cascading impact across your entire project ecosystem.

Performance Visibility Challenges Multiply with Scale

Performance measurement and reporting challenges multiply exponentially as your project portfolio grows. Without real time visibility into project status and quality metrics across diverse locations, operations managers struggle to:

- Identify Bottlenecks Early: Problems can fester unnoticed until they become critical and expensive to resolve

- Maintain Consistent Standards: Different projects using varying documentation formats make benchmarking impossible

- Implement Process Improvements: Lack of standardized data collection prevents systematic optimization

Without clear visibility, it’s easy to slip into reactive mode, spending more time tracking down project details than focusing on high level coordination and improvement.

2. The Documentation Foundation – Why Precision Matters HVAC Operations

Clear Documentation Prevents Installation Surprises

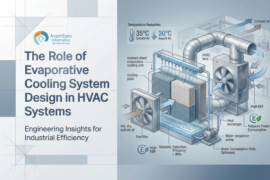

At the heart of many project delivery challenges lies inadequate documentation. When your HVAC CAD drafting is precise and comprehensive, field teams can work confidently without constant clarification requests. Detailed drawings that clearly show component relationships, dimensional requirements, and connection details eliminate guesswork in the field.

Professional solidworks drafting services provide the consistency and detail that operations managers need to coordinate multiple simultaneous projects effectively. When technicians can clearly understand how systems integrate, they can work more efficiently and identify potential issues before they become costly problems.

Standardized Processes Enable Better Resource Planning

Consistent drawings create the predictability needed for accurate resource scheduling. When every component, connection, and equipment specification is clearly documented using standardized formats, you can:

- Optimize Scheduling: Know exactly when and where technicians and materials are required

- Minimize Site Visits: Reduce unnecessary trips by providing complete information upfront

- Improve Communication: Ensure field teams, engineers, and project managers work from the same playbook

Quality Control Becomes Measurable

Standardized documentation formats across all projects create the foundation for meaningful performance measurement. When all projects use consistent drawing formats, symbols, and detail levels, you can establish reliable benchmarks and identify patterns in project performance.

3. Industry Context – Standards and Best Practices

The HVAC/R industry relies on clear documentation to meet both efficiency goals and compliance requirements. Industry standards like ASHRAE and SMACNA provide guidelines for HVAC equipment design and installation, and your drafting must align with these standards to ensure regulatory compliance and system performance.

Organizations that invest in robust drafting processes supported by standardized template libraries do consistently see:

- Smoother Project Handoffs: Clear documentation reduces confusion during project transitions

- Fewer Field Issues: Comprehensive drawings prevent installation surprises

- Better Overall Performance: Standardized processes enable continuous improvement

Implementation Strategies for HVAC Operations Managers

Successful implementation of improved documentation standards requires focusing on consistency and quality control:

- Establish Documentation Requirements: Create clear standards that support efficient field operations

- Implement Quality Control Processes: Regular documentation reviews before project mobilization prevent costly field delays

- Train Teams on Standards: Ensure field teams understand how to interpret and use high-quality project drawings effectively

4. How Asset-Eyes CAD Drafting Services Drive HVAC Operations Efficiency

At Asset-Eyes, our CAD drafting services are specifically designed to address the complex coordination requirements of multi-project HVAC/R operations. We understand how documentation quality directly impacts project delivery efficiency and resource utilization across large project portfolios.

Our Specialized Approach to HVAC Operations Documentation

Our team focuses on creating manufacturing-ready documentation that bridges the gap between design intent and field execution. Through our solidworks drafting services, we provide:

- Consistent Documentation Standards: Standardized drawing formats that eliminate confusion across multiple projects

- Detailed Component Integration: Clear general assembly drawings that show how complex HVAC/R systems integrate

- Precise Technical Specifications: Accurate dimensional details and connection requirements that prevent field surprises

- Electrical Control Panel Design Documentation: Detailed electrical schematics that ensure seamless integration with mechanical systems

Supporting Your Multi-Project Coordination

Our HVAC CAD drafting expertise helps operations managers achieve the predictability and visibility required for successful multi-project coordination:

- Scalable Solutions: Whether you’re managing two projects or twenty, our services maintain consistent quality

- Process Integration: We collaborate with your engineering and project management teams to align with your workflows

- Quality Assurance: Our documentation undergoes rigorous review to prevent the costly delays caused by incomplete or inaccurate information

We don’t perform design work that’s your engineering team’s responsibility. Instead, we translate your designs into the accurate, comprehensive documentation essential for seamless project execution, ultimately enhancing your project profitability and delivery efficiency.

Final Thoughts

The challenges of managing multiple HVAC/R projects simultaneously are complex, but they’re not insurmountable. By focusing on documentation quality and consistency, operations managers can create the foundation for more efficient project coordination and resource utilization.

Quality documentation isn’t just about creating better drawings, it’s about enabling better project delivery across your entire organization. When field teams have confidence in their project documentation, operations managers can focus on strategic coordination rather than crisis management. The investment in professional CAD drafting services pays dividends through reduced delays, improved communication, and more predictable project outcomes.

If you’re ready to transform your project delivery challenges into competitive advantages through precision documentation, we’re here to help.

Contact Us Now:

📞 +91 9840895134