A mid-sized HVAC/R manufacturer outsourced the design of a heat exchanger for their commercial chiller line, seeking faster time-to-market and specialized expertise. Initial prototypes excelled in controlled tests, showing a promising 15% efficiency improvement. Production launched with high expectations for a competitive edge in the industrial cooling market.

Within months, disaster struck. Service calls flooded in from distributors across regions, all reporting premature heat exchanger failures causing critical system shutdowns. Despite passing all standard quality protocols, components failed dramatically in real-world applications. The culprit? Microscopic stress fractures developing at critical brazing joints during thermal cycling.

A review revealed a fundamental disconnect between theory and practice. The outsourced team, had prioritized theoretical efficiency over practical manufacturability. They lacked critical experience with actual operating conditions. Their vibration analysis, conducted under idealized conditions, did not account for the changing mechanical stresses present in typical installations.

The manufacturer was forced to suspend production, recall units, and initiate a comprehensive redesign. Beyond the extra costs, the damage proved substantial: strained distributor relationships, canceled orders from major clients, and a tarnished reputation that would take years to rebuild. What began as a strategic initiative to enhance their product offering had instead undermined their entire market position.

If the scenario above sounds like a spider’s nest you wouldn’t touch with a ten-foot pole, you would be right to be skeptical about outsourcing in general. This blog delves into the do’s and dont’s of outsourcing, specifically for HVAC/R OEMs(Original Equipment Manufacturer) and examines the lucrative benefits as well as the potentially disastrous drawbacks if not done right.

Successful outsourcing requires understanding potential pitfalls and implementing specific prevention strategies to choose the right partner that supports your team to be as effective as possible.

Table of Contents

Navigate directly to any section by clicking the links below:

- The Appeal of Outsourcing for HVAC/R Equipment OEMs

- HVAC/R Design Outsourcing: Common Pitfalls & Effective Solutions

- Selecting the Right HVAC/R Design Partner

- Building a Successful Outsourcing Relationship

- Conclusion: Strategic Outsourcing for HVAC/R Design

The Appeal of Outsourcing for HVAC/R Equipment OEMs

Most HVAC/R equipment manufacturers are already familiar with the potential benefits of outsourcing design work:

Cost Efficiency: The cost of labor is reduced. What would have been fixed salaries are now variable expenses and the need to invest in specialized software is significantly lower.

Access to Specialized Expertise: Working with engineers who have the necessary domain knowledge particularly when dealing with heavy subject matter like complex thermal, fluid dynamics, or materials engineering helps when you inevitably reach a roadblock.

Scalability and Flexibility: Outsourcing presents a unique opportunity to respond to rapid market changes. This opportunity helps managers manage their resources in accordance with seasonal fluctuations.

Focus on Core Competencies: Working with a drafting partner helps to free your internal resources to improve manufacturing excellence, analyze market development, and plan their strategies to innovate.

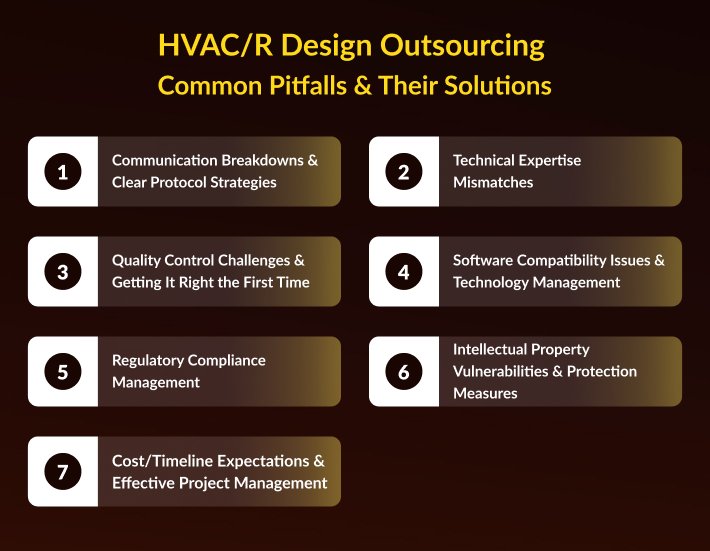

HVAC/R Design Outsourcing: Common Pitfalls & Their Solutions

1.Communication Breakdowns & Clear Protocol Strategies

Problem: Unclear specifications from the manufacturer’s side often lead to outsourced contractors doing a lot of guesswork to fill in the blanks while designing critical components like heat exchangers or refrigerant circuits, resulting in designs that will most likely fail to meet real world performance parameters leading to expensive, time-consuming re-designs.

Solution: Manufacturers today would benefit from developing comprehensive design requirement documents and participate in regular video conferences. These should ideally be held at strategically scheduled times to bridge time zone differences while maintaining clear communication channels. This lays the foundation for everyone involved being on the same page from day one.

2.Technical Expertise Mismatches

Problem: On occasion, vendors claim HVAC/R expertise but lack specific knowledge in thermal dynamics, refrigeration cycles, or airflow principles, leading to suboptimal designs which could lead to poor performance and failed efficiency standards.

Solution: Consider evaluating vendors specifically for similar HVAC/R equipment projects and conduct technical interviews focusing on HVAC/R principles to assess their actual capabilities. At Asset-Eyes Infomatics, we concentrate exclusively on HVAC/R equipment, bringing deeper understanding and more relevant experience to every project. We understand our clients’ manufacturing needs and design with production in mind.

3. Quality Control Challenges & Getting It Right the First Time

Problem: Quality checks that look great on paper often miss the mark in the real world. What sometimes happens is designs sail through digital reviews looking perfect, only to fail dramatically when actually built and installed.

For example: A heat exchanger that performs flawlessly during a simulation might develop stress fractures when subjected to thermal cycling in a real installation. Certain refrigeration components that meet specifications in isolation might interact poorly with certain coolants or vibration patterns.

These issues typically surface at the worst possible moments—during production runs, field installations, or worse, after customer delivery—leading to expensive recalls, emergency redesigns, and those painful conversations with unhappy clients that nobody wants to have.

Solution: Think of quality control like checking your work before submitting a final exam—you want to catch your own mistakes before the professor does. Develop HVAC/R-specific checklists that focus on common failure points rather than generic design standards. Get your technical team and manufacturing folks in the same room (virtually works too) to review designs together before anything gets built. The production team will spot manufacturability issues that designers might miss, while engineers can explain performance requirements that production needs to understand.

Ask challenging “what if” questions during these reviews: “What happens when this component faces extreme temperature swings?” or “How will this joint hold up under constant vibration?” This practical skepticism catches problems while they’re still just pixels on a screen—when fixes are quick and inexpensive. Remember, spending an extra day on thorough quality reviews can save weeks of rework down the road.

4.Software Compatibility Issues & Technology Management

Problem: File format conflicts between different CAD/BIM systems cause: data loss during transfers, corrupted models, or missing components, particularly in complex 3D refrigerant piping models.

Solution: Do define file format standards and software versions before project initiation and conduct test transfers of complex HVAC/R models to verify data integrity. For total transparency, clearly specify the key measurements needed for accurate manufacturing.

5.Regulatory Compliance Management

Problem: A vendor’s unfamiliarity with region-specific HVAC/R standards (ASHRAE, UL, BS/EN) will likely lead to designs that will fail certification and require substantial rework.

Solution: Provide your partners with all the reference materials for relevant HVAC/R codes and standards and create compliance checklists specific to your target markets. Alternatively, you could consider a hybrid approach: keep compliance verification in-house while outsourcing other design elements.

6.Intellectual Property Vulnerabilities & Protection Measures

Problem: Inadequate protection of proprietary HVAC/R technologies creates the risk of information leakage to competitors. Obviously, this would be far from ideal and would be a nightmare to explain to your boss.

Solution: Implement comprehensive NDAs with specific protections for HVAC/R technologies and compartmentalize sensitive design elements. Establish secure file transfer protocols and regular security audits for everyone’s peace of mind.

Real-World Example: The Target security breach of 2013 began when hackers compromised an HVAC/R vendor with legitimate access to Target’s network. While primarily a cybersecurity issue, it demonstrates how third-party relationships require robust protection measures—whether for network access or proprietary design information.

7.Cost/Timeline Expectations & Effective Project Management

Problem: Hidden costs and scope creep in complex HVAC/R design projects lead to budget overruns and missed market windows.

Solution: Become a savvy outsourcing partner rather than a bargain hunter by looking beyond tempting hourly rates. Demand transparent pricing structures that clearly define what’s included and what triggers additional charges. Watch for common traps: excessive revision fees, unexpected consultation charges, and file conversion costs that quickly inflate budgets.

Negotiate fixed-price agreements for well-defined project phases where possible, shifting cost overrun risk to vendors while creating incentives for efficient delivery. Tie payments to quality milestones rather than just completion dates—you’re paying for results, not effort. Build in a modest contingency budget (10-15%) for inevitable minor adjustments.

Maintain structured check-ins between your team and outsourced partners to detect scope creep early, before it cascades into budget disasters. This balanced approach captures the genuine cost advantages of outsourcing while protecting against hidden expenses that transform apparent bargains into financial headaches.

Selecting the Right HVAC/R Design Partner

Critical Evaluation Criteria

When evaluating potential HVAC/R design partners, focus on these essential qualifications:

- Specific experience with similar HVAC/R equipment types

- Demonstrated understanding of systems engineering

- Quality assurance processes tailored to HVAC/R design challenges

- Reliable communication infrastructure

- Geographic expertise relevant to target markets

Red Flags to Watch For

Be wary of potential partners who display these warning signs:

- Vague responses about specific HVAC/R experience

- Inability to discuss technical refrigeration or thermal concepts fluently

- Inadequate explanation of quality control processes

- Lack of familiarity with relevant industry standards

- Unclear policies regarding intellectual property protection

Building a Successful Outsourcing Relationship

Effective Onboarding Process

The foundation of successful design outsourcing is a thorough onboarding process:

- Ensure you conduct a structured knowledge transfer of your company standards and expectations. This should include a detailed walkthrough of your protocols, quality benchmarks, and any critical processes, so that the outsourced team is fully aligned with your operating procedures

- Conduct comprehensive training for your product-specific requirements and clearly communicate the established design philosophy

- Arrange an introduction to key stakeholders across all departments to foster good relationships

- Provide clear documentation of your communication channels and escalation procedures

Asset-Eyes Infomatics has developed a specialized onboarding framework for HVAC/R manufacturers that reduces ramp-up time by 40% compared to traditional approaches. Our technical immersion program ensures design teams understand not just specifications, but the underlying performance principles critical to your equipment’s success.

Ongoing Relationship Management

Long-term success requires continuous attention to the partnership:

- Conduct regular performance reviews using established metrics

- Develop continuous improvement processes for workflow optimization

- Invest in relationship building beyond transactional interactions

- Development of long-term partnership strategy

Our client success managers at Asset-Eyes maintain regular cadence meetings with both technical and business stakeholders, ensuring alignment as projects evolve. This proactive approach has helped our HVAC/R clients reduce design iterations while accelerating time-to-market for new equipment designs.

Conclusion

When approached strategically, outsourcing HVAC/R equipment design can deliver significant competitive advantages. The key is recognizing that successful outsourcing requires more than just finding the lowest-cost provider—it demands careful partner selection, clear communication protocols, robust quality assurance processes, and ongoing relationship management.

By implementing the preventative measures outlined in this article, you can harness the benefits of outsourcing while avoiding the costly pitfalls that other manufacturers have paid the ultimate price for.

Remember that some design elements may be better kept in-house, particularly those involving proprietary technologies or critical competitive advantages. A hybrid approach often yields the best results, combining internal expertise with external capabilities in a carefully orchestrated partnership.

Ready to explore how strategic design outsourcing could enhance your HVAC/R equipment development? Schedule a consultation with our HVAC/R/R design specialists today by calling +91 9840895134 or emailingsales@asset-eyes.com. We typically respond within 48 hours. Our team is ready to discuss your specific challenges and how our specialized expertise can help you achieve your design and manufacturing goals!