Table of Contents

- The Problem: Design Inefficiency Costs

- Real-World Impacts

- Design Efficiency Strategies

- 1. Eliminating Over-Engineering

- 2. Integrated Engineering Approach

- 3. Scalable Design Methods

- 4. Process Optimization

- Our Specialized Expertise

- Conclusion

The Hidden Cost of Design Inefficiency

In today’s competitive HVAC&R manufacturing landscape, design inefficiencies aren’t just frustrating—they’re profit killers. While most manufacturers recognize bottlenecks exist, few have quantified their true impact on the bottom line:

- Late-stage redesigns adding weeks to production timelines

- Over-engineered systems driving up unnecessary costs and complexity

- Inefficient workflows delaying time-to-market, costing valuable deals and market share

When margins are tight and competition is fierce, these inefficiencies directly impact profitability. At Asset-Eyes Infomatics, we partner with HVAC&R equipment manufacturers to streamline design processes, eliminate wasteful practices, and accelerate the delivery of production-ready systems.

The Real-World Impact of Inefficient HVAC&R Design

Before exploring solutions, let’s highlight what’s truly at stake:

- Extended Production Timelines: Each design revision can add 2-4 weeks to your production schedule, delaying revenue generation

- Increased Material Costs: Over-engineered systems typically inflate material costs by 15-25%

- Reduced Competitiveness: Slower time-to-market means missing critical opportunities and losing ground to more agile competitors

Design Efficiency Strategies

1. Eliminate Over-Engineering: Precision Without Waste

The Problem: Many HVAC&R systems suffer from habitual over-engineering—components selected by tradition rather than necessity, unnecessarily complex layouts, and redundant safety margins that inflate costs while creating maintenance challenges.

Our Solution: We apply precision engineering principles to create leaner, high-performance systems. Every component must earn its place in the design, eliminating redundancies while maintaining compliance and reliability.

Impact: Manufacturers reduce material wastage, lowering energy consumption, and significantly improving cost efficiency without sacrificing design quality.

Takeaway: The best designs can achieve peak performance, while saving you time and money during every stage of production.

2. Integrated Engineering: Breaking Down Design Silos

The Problem: When mechanical, electrical, and automation engineering teams work in isolation, you can probably expect: last-minute changes, schematic errors, and compatibility issues that cause production delays.

Our Solution: We implement a unified design approach that coordinates all engineering disciplines from project inception. Expertise in electrical control panel design and motor control panel design ensures seamless integration across all system components.

Our integrated approach includes:

- Coordinated mechanical and electrical system development

- Comprehensive control panel design that aligns with mechanical requirements

- Synchronized documentation using advanced HVAC CAD drafting

Impact: Systems that work harmoniously together, dramatically reducing rework, delays, and unexpected costs during manufacturing.

Takeaway: Successful HVAC&R equipment must be designed as a cohesive system, not as disconnected components forced to work together after the fact.

Is your engineering team working in silos? Schedule a consultation to discover how our unified approach can transform your workflow and reduce costly redesigns by up to 40%.

3. Scalable Design: Engineering Systems That Grow With Your Business

The Problem: Repeatedly designing one-off systems for each new project drains engineering resources and significantly slows production cycles.

Our Solution: We implement scalable design principles that enable manufacturers to develop product families instead of isolated units. Using SolidWorks drafting services and SolidWorks 2D drafting, we create modular templates that can be efficiently adapted across multiple models.

Our scalable approach includes:

- Creating standardized component libraries

- Developing modular designs that can be reconfigured for different capacities

- Optimizing bills of materials (BOMs) across product lines

- Establishing consistent general assembly drawing standards

Impact: Dramatically faster iterations, reduced engineering overhead, and a competitive advantage in bringing new products to market quickly.

Takeaway: Scalable designs don’t just reduce current costs—they position your business for more efficient growth and faster market response.

4. Process Optimization: Accelerating Delivery Without Compromising Quality

The Problem: Many manufacturers unknowingly rely on disjointed workflows that lead to repetitive tasks, approval bottlenecks, and inefficient collaboration.

Our Solution: We optimize the entire design process—from concept to production—by implementing structured workflows that eliminate redundancies. CAD drawing services streamline documentation while maintaining precision.

Our process improvements include:

- Standardized design validation protocols

- Streamlined approval workflows

- Efficient documentation management

- Coordinated design review processes

Impact: Faster turnaround times, fewer revisions, and a clear path from concept to production.

Takeaway: True efficiency comes from eliminating workflow bottlenecks and wasted effort, not just automating existing processes.

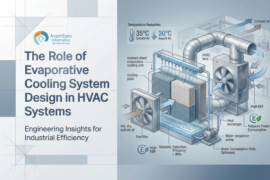

Specialized Expertise for Complex Systems

As a leading machine design company, we bring specialized knowledge to challenging applications, including:

- Industrial ventilation system design that optimizes airflow while minimizing energy consumption

- Industrial exhaust system design that ensures regulatory compliance and worker safety

- Evaporative cooling system design that maximizes efficiency in commercial applications

By combining deep technical expertise with process optimization, we deliver solutions that outperform traditional approaches in both efficiency and effectiveness.

Designing for Efficiency is Designing for Profitability

Optimized HVAC&R designs don’t just perform better—they cost less to produce, command higher margins, and reach the market faster. At Asset-Eyes, we help manufacturers:

- Eliminate wasteful over-engineering in HVAC&R equipment design

- Integrate mechanical, electrical, and automation engineering seamlessly

- Create scalable designs for faster production and market adaptation

- Structure workflows to maximize efficiency at every stage

Our comprehensive approach combines the precision of specialized engineering with practical efficiency improvements that directly has an impact on your bottom line. Ready to explore how strategic design outsourcing could enhance your HVAC/R equipment development? Schedule a consultation with our HVAC/R/R design specialists today by calling +91 9840895134 or emailing sales@asset-eyes.com or visiting our site asset-eyes.com to explore our capabilities. We typically respond within 48 hours. Our team is ready to discuss your specific challenges and how our specialized expertise can help you achieve your design and manufacturing goals!