Ever watched a skilled technician squint at a control schematic, hesitate, then make their best guess at a connection? If you’ve seen that moment of uncertainty on your production floor, you know it’s not just about individual performance it’s about systemic inefficiency that quietly drains your bottom line. In HVAC/R manufacturing, the difference between documentation that looks professional and documentation that actually works can be measured in hundreds of thousands of dollars. A recent project with an industrial chiller manufacturer proves this point dramatically. Their story shows how smart design eliminated $120,000 in annual waste while cutting training time by 35%. The lesson is clear: when it comes to technical drawings, clarity isn’t just nice to have, it drives profitability.

1. The Challenge: When Technical Accuracy Isn’t Enough

This industrial chiller manufacturer specialized in advanced CO2 refrigeration systems and took pride in their engineering excellence. Their electrical control panel drawings were technically accurate: every wire, every connection, every component was precisely documented according to engineering standards. On paper, everything looked perfect.

The reality on their production floor told a different story. Technicians were struggling with complex schematics that, while technically correct, didn’t align with how people actually think and work. The symptoms were costly and persistent.

Assembly errors were frequent and expensive. Misinterpreted wires led to incorrect connections that might not be discovered until system testing. By then, the cost included diagnostic time, rewiring labor, replacement materials, and schedule delays that rippled through other production activities.

Rework cycles were disrupting schedules. Every error meant pulling units off the line, troubleshooting the problem, and completing corrections all while other work backed up behind the bottleneck.

New technician training had become a significant constraint. Bringing new hires up to competency on control systems required extensive supervision from senior staff, limiting the company’s ability to scale production quickly.

The numbers were sobering: approximately 12 assembly errors per month across their production lines, with each error costing between $800 and $1,200 in direct costs, plus schedule impact averaging another $900. That’s roughly $2,100 per error, or $252,000 annually in preventable waste money that was literally disappearing due to documentation that failed to serve its primary users effectively.

2. Our Solution: Designing Documentation for Human Performance

Instead of simply redrawing their existing documentation with cleaner formatting, we fundamentally redesigned it for the people who actually use it every day. The goal was not to make things look prettier. We wanted to make complex electrical systems intuitively understandable for technicians working under real production pressures.

We incorporated ladder logic formatting principles that structured the schematics to mirror actual electrical flow: power source flowing through the main controller to the controlled devices. Rather than forcing technicians to mentally translate engineering schematics into practical wiring sequences, we made the documentation follow their natural thought processes.

Our organized information by workflow, not just by engineering logic. The drawings now answered the fundamental questions technicians ask in sequence: “Where does power come from? What controls what? Which connections happen first?” This eliminated the cognitive translation steps that created opportunities for error.

We enhanced visual clarity through consistent symbols, clear device tagging, and explicit cross references that eliminated wire tracing detours. Terminal strip drawings included side views with wiring ferrule callouts, and panel layout drawings showed physical component spacing alongside electrical connections.

The transformation involved our electrical control panel design experts to create documentation that bridged the gap between engineering precision and shop floor practicality. Technical accuracy remained intact, but the drawings became genuinely usable under real world conditions.

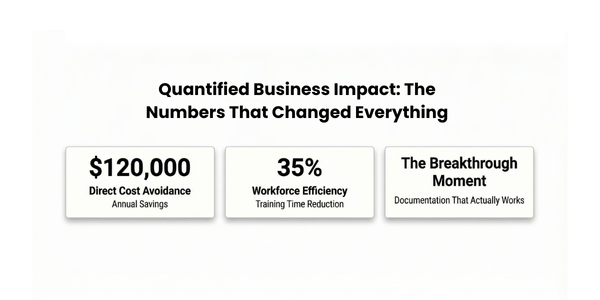

3. Quantified Business Impact: The Numbers That Changed Everything

Direct Cost Avoidance: $120,000 Annual Savings

The results were immediate and measurable. By improving documentation clarity, we achieved a 40% reduction in assembly errors from 12 errors per month down to approximately 7.2 errors per month. With each error costing an average of $2,100 (including direct costs and schedule delays), this translated to avoiding 57.6 errors annually.

Let me break down the mathematics:

- Previous error rate: 12 errors per month

- 40% reduction: 12 × 0.40 = 4.8 fewer errors per month

- Annual error reduction: 4.8 × 12 months = 57.6 errors avoided

- Cost per error: $2,100 (labor + materials + schedule impact)

- Annual savings: 57.6 × $2,100 = $120,960

This wasn’t theoretical improvement, it was money that stayed in the company’s account instead of being spent on preventable rework.

Workforce Efficiency: 35% Training Time Reduction

Beyond error reduction, we achieved a 35% decrease in new technician training time for control system competency. New hires were reaching independence in 4 weeks instead of the previous 6 weeks, saving approximately $4,000 per technician in supervision and ramp up costs.

In today’s tight labor market, this training efficiency provides strategic advantages beyond immediate cost savings. Companies that can bring new technicians up to speed faster have better scaling capability and can respond more quickly to increased demand or staff turnover.

The Breakthrough Moment: Documentation That Actually Works

The real validation came during a critical project deadline when a technician with just 3 weeks of experience successfully completed control panel wiring independently, something that previously required constant senior oversight. This wasn’t about exceptional individual ability, it was about documentation that had become truly intuitive.

When experienced supervisors can focus on higher value activities instead of constantly checking basic wiring work, the productivity gains extend far beyond the immediate task. Senior technicians become force multipliers rather than bottlenecks, and project schedules become more predictable and reliable.

4. Why Smart Documentation Design Works: The Human Performance Factor

Exceptional engineering documentation isn’t just about technical accuracy, it’s about enabling human performance under real world conditions. The best schematics don’t just show what needs to be done, they guide technicians through the logical sequence of actions needed to accomplish the work correctly and efficiently.

The key insight is understanding the difference between information and communication. Information is accurate technical data. Communication is organizing that data in ways that enable effective action. When documentation communicates effectively, errors decrease, training time shrinks, and productivity increases across the entire production operation.

In HVAC equipment design and industrial refrigeration systems, control complexity is constantly increasing. Variable frequency drives, multiple sensor inputs, staged control sequences, and integrated building management systems create challenges that can overwhelm even experienced technicians if the documentation doesn’t provide clear guidance.

Companies with clear, usable documentation can scale faster, train quicker, and deliver more consistently than competitors struggling with complex, hard to follow technical drawings. In manufacturing environments where skilled labor is increasingly scarce and expensive, documentation quality becomes a competitive differentiator that directly impacts profitability.

5. Practical Implementation: How to Apply These Principles – Smart Design

Based on this success and similar projects, several key principles emerge for creating documentation that actually improves performance:

Structure Schematics by Logical Flow

- Power distribution first, then controls, then devices and loads

- Use ladder style left to right power and control notation where appropriate

- Organized by the sequence technicians actually follow during assembly

Make Navigation Effortless

- Include sheet indexes, zone grids, and jump references (e.g., “To Sheet 6, Zone C3”)

- Use consistent device tags (CHLR-CP-001, TB1-12, MTR-02) with master legends

- Provide clear cross references that eliminate wire tracing detours

Eliminate Ambiguity Through Precision

- Include wire numbers, cable IDs, termination tables, and point to point schedules

- Add terminal strip drawings with side views and wiring ferrule callouts

- Create panel layout drawings that show physical spacing alongside electrical connections

Support Installation and Testing

- Provide mechanical general assembly drawings callouts for breaker sizes, component spacing, and interconnects

- Include commissioning checklists, I/O maps, and functional test notes in the documentation package

- Smart Design drawings that support troubleshooting, not just initial assembly

Industry Standards Alignment While documentation needs to fit your internal standards, aligning with recognized frameworks helps ensure consistency and familiarity:

- UL 508A standards for industrial control panels in North America

- NFPA 70 (NEC) and NFPA 79 for industrial machinery electrical requirements

- IEC 60617 and IEC 81346 for international symbol and structuring conventions

- IEC 61131-3 concepts for ladder logic notation where applicable

6. How Asset-Eyes Transforms Your Documentation Challenge -Smart Design

At Asset-Eyes, our approach to HVAC CAD drafting and electrical control panel design focuses on creating documentation that enables superior human performance, not just technical accuracy. We understand that the best drawings are those that help technicians work faster, more accurately, and with greater confidence.

Our cad drafting service emphasizes practical usability alongside engineering precision. Through our solidworks drafting services, we create comprehensive documentation packages that guide technicians through complex assembly sequences while maintaining the technical rigor required for reliable system operation.

Our role is translating your engineering intent into documentation formats that eliminate confusion, reduce errors, and accelerate production. When control panel schematics follow logical flow patterns and connection sequences are immediately obvious, manufacturing teams can execute your smart design with consistency and confidence.

Whether you need specialized electrical control panel design documentation, comprehensive general assembly drawing packages, or precise 2d drafting in solidworks that supports your manufacturing processes, we focus on creating deliverables that bridge the gap between engineering excellence and shop floor efficiency.

7. The Strategic Advantage: Documentation as Competitive Weapon

The $120,000 annual savings achieved through better documentation smart design represents a conservative calculation based on industry standard costs and typical improvement rates. Many companies see even greater benefits when documentation clarity enables faster product development cycles, reduces field service calls, and improves customer satisfaction.

Consider the broader implications: when your documentation enables faster training, you can expand production capacity more quickly in response to market opportunities. When assembly errors decrease, your delivery schedules become more reliable, improving customer relationships and reducing expediting costs. Then when experienced technicians spend less time troubleshooting documentation issues, they can focus on process improvements and quality enhancements.

When control systems are becoming increasingly sophisticated and skilled technicians are increasingly valuable, documentation quality directly impacts profitability. Companies that invest in making their technical communication truly effective gain sustainable competitive advantages that compound over time.

Your documentation is either helping your team perform at their best, or it’s quietly costing you money every day through inefficiency, errors, and extended training cycles.

Strong documentation pays for itself, weak documentation quietly drains your profits.

Contact Us Now:

📞 +91 9840895134