If you’ve experienced the frustration of unexpected equipment failures, inflated energy costs, or wear and tear that shortens equipment lifespan, you’re dealing with challenges that proper motor control selection can solve. In today’s industrial landscape, the choice between soft starters and variable frequency drives (VFDs) is all about optimizing performance, protecting your investment, and ensuring smooth operation across your entire system. Understanding when to use each technology and how to integrate them effectively can transform your motor control applications from potential headaches into competitive advantages. This guide explores the key differences, selection criteria, and integration strategies that will help you make informed decisions for your specific applications.

1. Understanding Soft Starters: The Gentle Approach to Motor Control

When you start a large electric motor directly across the line, it draws an inrush current that’s typically 6-8 times its normal operating current. This sudden surge creates mechanical shock, stresses electrical components, and can cause voltage sags throughout your facility. Soft starters address this issue by enabling controlled acceleration and deceleration.

A soft starter works by gradually increasing the voltage applied to the motor during startup, typically reducing inrush current to just 2-4 times full load current. Think of it as the difference between flooring the accelerator versus gradually pressing it down both get you moving, but one is much gentler on the system.

Key advantages of soft starters include:

- Reduced mechanical stress on belts, gears, couplings, and driven equipment, extending component life significantly

- Lower electrical stress on your power system, reducing demand charges and preventing voltage sags that affect other equipment

- Smooth operation that’s particularly valuable for applications where sudden acceleration could damage products or processes

- Cost-effectiveness compared to VFDs when speed control isn’t required during operation

Soft starters do well when they are used in applications like centrifugal pumps, compressors, large fans, and conveyor systems where the focus is on controlling continuous starting and stopping and not on changing the speed during any operation. They’re particularly valuable when dealing with high-inertia loads or when your electrical system has limited capacity to handle starting surges.

However, soft starters have limitations worth considering. They don’t provide speed control during operation, offer limited energy savings potential, and continue to consume full power once the motor reaches operating speed. For applications requiring variable speed operation or significant energy efficiency improvements, you’ll need to look at VFDs.

2. Variable Frequency Drives: Precision Control and Energy Efficiency – Integration Strategies

Why would you use a VFD? One of the reasons may be because they offer precise speed and torque control by varying both voltage and frequency supplied to the motor. Another reason might be because unlike soft starters, they provide continuous control across all speed levels. This is why they have the edge over soft starters and are ideal for applications where the speed needs to be changed on the go.

The financial benefits (energy savings) alone are substantial, particularly in centrifugal applications like fans and pumps. This is due to the cube law relationship, where power consumption varies with the cube of speed:

P2=P1×(N1/N2)3

Where:

- P₁

- P₂

- N₁

- N₂

This can also be expressed as a proportionality relationship:

P∝N3

This means that cutting motor speed by only 20% can lead to about a 50% decrease in power consumption. For a 100 HP motor running 8,760 hours annually, this could translate to significant cost savings depending on your local electricity rates.

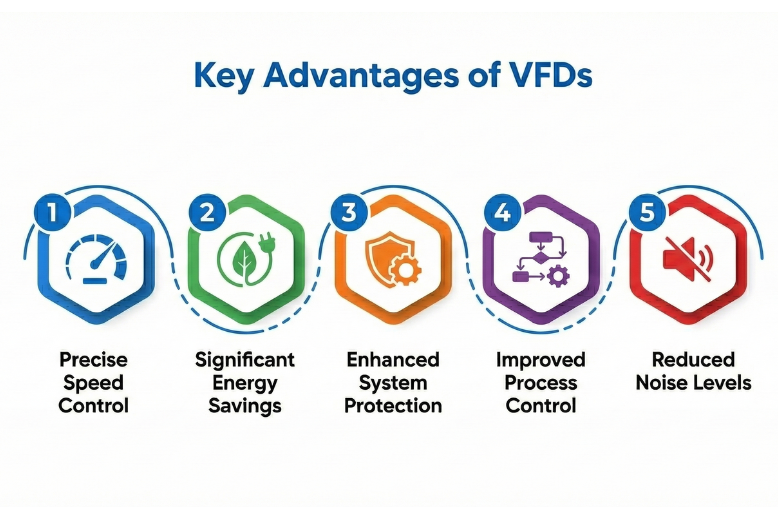

VFDs offer several key advantages:

- Precise speed control throughout the operating range, enabling optimal process control

- Variable torque applications often achieve substantial energy savings, allowing VFDs to pay for themselves within 1 to 3 years.

- Improved system protection through integrated monitoring and diagnostic features.

- Improved process control allowing for better product quality and system optimization

- Reduced noise levels when operating at lower speeds

In industrial ventilation and evaporative cooling system design, the capability to adjust motor speed according to changing demands is crucial. VFDs enable this level of responsiveness by allowing motors to match system requirements in real time, improving both energy efficiency and process control. Whether it’s managing airflow in large-scale ventilation setups or optimizing water flow in evaporative cooling units, VFDs play a critical role in ensuring performance stays aligned with changing operating conditions.

The complexity of VFDs presents both benefits and challenges. While they offer superior control and energy efficiency, they require more sophisticated installation, including proper grounding, EMI filtering, and harmonic mitigation. These considerations become critical factors in your electrical control panel design.

3. Selection Criteria: Making the Right Choice for Your Application with Integration Strategies

Choosing between soft starters and VFDs requires systematic evaluation of your specific requirements. Here’s a clear step-by-step guide to assist you in making your decision:

Step 1: Analyze Speed Requirements

- Does your application require variable speed during operation? If yes, VFDs are necessary

- Is controlled starting and stopping sufficient? Soft starters may be adequate

- Are there process benefits from speed variation? Consider VFDs for optimization potential

Step 2: Evaluate Energy Savings Potential

- Calculate potential energy savings using the cube law for centrifugal loads

- Consider your facility’s energy costs and operating hours

- Consider utility rebates or incentives available for energy-efficient equipment.

Step 3: Assess Load Characteristics

- Constant torque loads, such as conveyors and positive displacement pumps, can effectively utilize either technology,

- while variable torque loads (such as centrifugal fans and pumps) usually prefer VFDs for better energy savings.

- High-inertia loads may require soft starters at minimum to prevent mechanical stress

Step 4: Consider System Integration Requirements

- Evaluate compatibility with existing control systems

- Assess available panel space and cooling requirements

- Consider maintenance capabilities and complexity tolerance

Step 5: Perform Economic Analysis

- Compare total cost of ownership, including installation, energy, and maintenance costs

- Calculate the payback period for VFDs by evaluating the energy savings they provide..

- Consider operational benefits like improved process control or reduced downtime

In industrial ventilation system design, a large exhaust fan running at a fixed speed may only require a soft starter to avoid power surges during startup. However, when that same fan must adjust its speed in response to occupancy levels or changing process needs, a VFD becomes essential as it delivers both energy savings and precise control.

4. Integration Strategies for Optimal Performance

To get motor control systems working properly, you need to make sure the electrical parts, mechanical setup, and control system all work well together. The way your team approaches this is going to be different when comparing the use-cases for soft starters and VFDs.

Electrical Integration Strategies Considerations:

For soft starters, focus on:-

- proper sizing

- bypass contactor selection

- coordination with existing motor protection devices

The electrical integration strategies is typically straightforward, requiring standard power connections and basic control wiring for start/stop signals.

VFD integration calls for a more thorough electrical setup.

- Proper grounding techniques to prevent EMI issues and ensure safe operation

- Harmonic mitigation using line reactors or filters to maintain power quality

- EMI filtering to prevent interference with other electronic equipment

- Control system integration requiring careful attention to communication protocols and safety interlocks

Mechanical Integration Strategies Factors:

At certain speeds, they can make the system vibrate in ways that weren’t expected. This happens because they can create frequencies that match the natural vibration of parts of the machine, like ducts, fans and mounts. That match can make the vibration stronger, which might cause noise or damage if not dealt with. Motors that are used for long periods at low speeds may need special consideration for bearing lubrication and cooling.

Documentation and Drafting Requirements:

Comprehensive documentation is essential for successful installation and long-term maintenance. This includes detailed schematics showing power and control wiring, precise panel layouts with component placement and wire routing, and complete bills of materials with specifications.

5. Industry-Specific Applications and Economic Considerations

Different industries present unique opportunities for motor control optimization. In HVAC CAD drafting, VFDs have become standard for VAV systems and chilled water pumps, where they interface with building automation systems to optimize energy consumption based on what the demand is in real-time.

Water treatment facilities benefit significantly from VFD technology for pump control, allowing precise flow control and substantial energy savings. The ability to maintain constant pressure despite varying demand makes VFDs particularly valuable in these applications.

Manufacturing environments often require both technologies. Main conveyor drives might use soft starters for reliable operation, while process equipment employs VFDs for precise control. The key is matching the technology to the specific requirements of each application.

The economic comparison extends beyond initial purchase price to include installation costs, energy consumption, maintenance requirements, and operational benefits. VFDs typically cost 20-30% more initially than soft starters but can provide substantial energy savings that often justify the investment within 1-3 years for appropriate applications.

6. Asset-Eyes: Supporting Your Motor Control Integration Success

At Asset-Eyes, our expertise in electrical control panel design and motor control panel design ensures that your technology selection translates into reliable, well-documented systems. Our team understands the complex integration requirements of both soft starters and VFDs, particularly in HVAC equipment design and industrial applications.

Through our CAD drafting service and SolidWorks design capabilities, we create comprehensive documentation that addresses every aspect of motor control integration. From detailed wiring diagrams to precise panel layouts, our mechanical general assembly drawing services provide the foundation for successful installation and long-term operation.

Our experience with machine design company requirements means we understand how proper documentation bridges the gap between design intent and field installation. Whether you’re implementing soft starters for controlled starting or VFDs for energy efficiency and process control, we ensure every connection, safety device, and control interface is clearly documented for your installation team.

Conclusion: Optimizing Your Motor Control Strategy

Selecting between soft starters and VFDs isn’t just about the technology, it’s about understanding your specific application requirements and ensuring proper integration through comprehensive documentation. Soft starters provide cost-effective solutions for controlled starting and stopping, while VFDs offer energy savings and precise control for variable speed applications.

The key to success lies in systematic evaluation of your requirements, careful consideration of economic factors, and meticulous attention to integration details. With proper selection and documentation, your motor control systems will provide reliable operation, energy efficiency, and long-term value.

Ready to transform your motor control concepts into precise, buildable documentation? Our team is here to support your success with comprehensive CAD drawings services that ensure reliable installation and operation.

Contact Us Now:

📞 +91 9840895134