Midweek chaos, as usual, sets in while you juggle three urgent product development projects at the same time. Your lead mechanical engineer is deep in a debate with the software team about IoT integration requirements, each side trying to align on what the final system really needs. Your phone buzzes again with yet another regulatory update that could easily affect your launch timeline if not addressed quickly. On top of that, there’s a red flag from the manufacturing team about a design detail that might be difficult or expensive to build in large volumes. Meanwhile, your CEO is asking why competitors seem to be launching products much faster than your team. If you’re an engineering director in HVAC/R manufacturing, this scenario probably feels very familiar.

The push to speed up product innovation while maintaining high quality has never been tougher. Traditional development methods can’t keep up anymore. This guide explores why modern HVAC equipment design is now a complex balancing act and how strategic documentation partnerships can help your team accelerate innovation without losing quality. Let’s move on to what we’ll cover.

1. The Perfect Storm of Modern Product Development Pressures

1.1 Cross-Functional Coordination Complexity

Today’s HVAC/R systems combine mechanical complexity with advanced technology, requiring seamless integration across multiple engineering disciplines. Your team must coordinate.

- Mechanical engineers who understand thermodynamics

- Electrical engineers handling power systems

- Controls specialists programming complex algorithms

- Software developers creating connectivity features.

Each team member speaks a different technical language, yet they all need to work toward a unified product vision. For example, when the mechanical engineer designs an optimal configuration for a heat exchanger, it must accommodate the electrical team’s power requirements, the controls team’s sensor placement needs, and the software team’s data collection protocols.

The challenge multiplies when you consider that modern HVAC systems increasingly incorporate IoT sensors, advanced controls, and connectivity features requiring expertise far beyond traditional mechanical engineering.

1.2 The Customization vs. Standardization Dilemma

You can expect evolving market demands to create friction when trying to balance efficiency and flexibility. Customers want tailored solutions specific configurations for unique applications, modified control sequences, custom form factors. But your manufacturing team needs standardization to maintain efficiency and cost targets.

This tension should be mitigated by your documentation protocol. Custom features must be captured accurately in your CAD drawings without overwhelming your production team with any new complexity. You need documentation pipelines that can handle both standard assemblies and custom variations efficiently, ensuring clear communication to manufacturing regardless of configuration complexity.

1.3 Regulatory Compliance Maze

The regulatory environment continues to grow in complexity. Energy efficiency standards evolve, refrigerant regulations change and safety certifications require new testing protocols. Each regulatory shift can impact multiple aspects of your product design, from component selection to control algorithms.

International markets compound this challenge exponentially. Products intended for global markets must meet diverse and sometimes conflicting regulatory requirements. Your documentation must support compliance across multiple jurisdictions while maintaining design integrity and manufacturing efficiency.

2. The Hidden Development Bottlenecks – Engineering Director

2.1 Documentation as a Development Accelerator or Brake

Here’s something most people don’t realize: a significant portion of product development delays aren’t caused by engineering challenges, they’re caused by documentation bottlenecks. Your brilliant engineers spend countless hours creating technical drawings, updating specifications, and maintaining design documentation instead of focusing on core innovation.

When design changes occur (and they always do), the documentation update process can consume weeks. Every drawing requires revision, every specification document needs updates, and every manufacturing instruction must be modified. This administrative burden significantly slows development cycles.

Poor documentation quality creates downstream problems that circle back to engineering. When manufacturing teams can’t interpret drawings clearly, or when installation teams encounter ambiguous specifications, your engineering team gets emergency calls to resolve problems that proper documentation could have prevented.

2.2 Design to Manufacturing Reality Checks

Your most elegant design solutions often require manufacturing precision beyond current equipment capabilities. Tight tolerances that optimize performance might demand new tooling or assembly processes. Component suppliers might not deliver specialized parts within cost targets.

Value engineering becomes a constant negotiation between technical optimization and commercial viability, requiring precise documentation that supports both design intent and production reality.

3. Strategic Documentation Solutions for Engineering Director

3.1 Parallel Processing Approach

The most strategic engineering director have realized that not every task requires internal engineering expertise. While your team’s knowledge is irreplaceable for innovation and problem-solving, the documentation work that supports these efforts can be handled by specialized partners.

Professional HVAC CAD drafting services can take documentation burdens off your engineering team’s shoulders. When your mechanical engineer completes a design concept, specialized drafting teams can create production ready drawings while your engineer moves on to the next innovation challenge.

This parallel processing approach accelerates development cycles because documentation work happens simultaneously with engineering work rather than sequentially. Your engineers stay focused on solving complex technical problems while drafting experts handle the detailed documentation that manufacturing teams require.

3.2 Consistency Across Development Cycles

Specialist vendors that understand HVAC/R systems can provide consistent documentation standards across all your projects. This consistency reduces learning curves for manufacturing teams, minimizes interpretation errors, and creates reliable templates for future development work.

Standardized documentation approaches also support regulatory compliance efforts by ensuring consistent information capture and presentation across all product lines. When regulatory agencies or certification bodies request documentation, you’ll have everything organized and ready.

4. Reclaiming Engineering Director Bandwidth

Successful implementation requires careful consideration of your team’s specific workflow and communication patterns. Start by identifying the documentation tasks that consume the most engineering time without requiring deep technical decision-making. These tasks are low hanging fruit for delegating to external partners

Clear, detailed drawings help bridge communication gaps between mechanical, electrical, and controls teams while providing manufacturing with actionable instructions.

Focus on documentation standards that support both standardization and customization needs. Your drafting processes should handle routine configurations efficiently while accommodating special requirements without creating confusion.

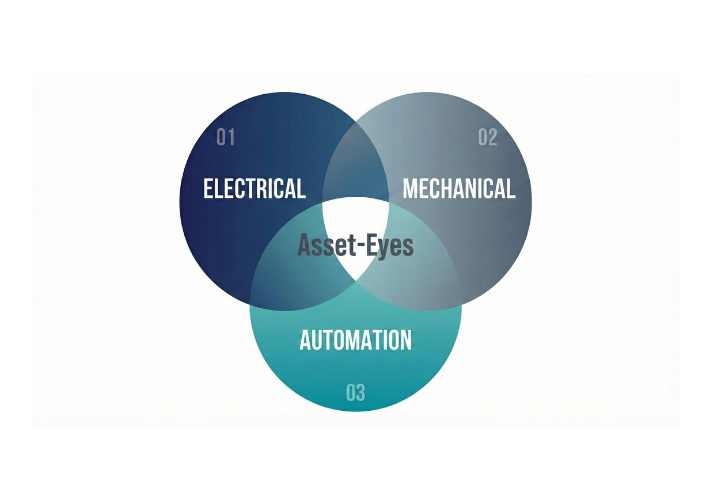

Asset-Eyes: Your Development Acceleration Partner

At Asset-Eyes, our CAD drafting services are specifically designed to support engineering directors facing these exact challenges. Our team understands the technical requirements of HVAC equipment design and can create manufacturing-ready documentation that bridges the gap between innovative design concepts and practical production requirements.

Through our specialized HVAC CAD drafting expertise, we ensure your engineering team’s innovations are properly documented for successful manufacturing and installation. Our solidworks drafting services support both standard product lines and custom configurations, providing the flexibility your market demands while maintaining the consistency your production team needs.

We help accelerate your development cycles by handling detailed documentation work in parallel with your engineering activities, freeing your team to focus on innovation, problem-solving, and technical leadership.

Moving Forward with Confidence

Managing product development pressures in today’s HVAC/R industry requires strategic thinking about resource allocation. Your engineering team’s expertise is your most valuable asset, use it for innovation, problem-solving, and technical leadership. Partner with specialists for the supporting work that enables your engineers to focus on what matters most.

The companies that thrive in this environment recognize when to build internal capabilities and when to leverage external expertise. Documentation and drafting work fall squarely in the category where specialized partners can deliver better results faster than internal teams stretched across multiple priorities.

Contact Us Today:

📞 +91 9840895134