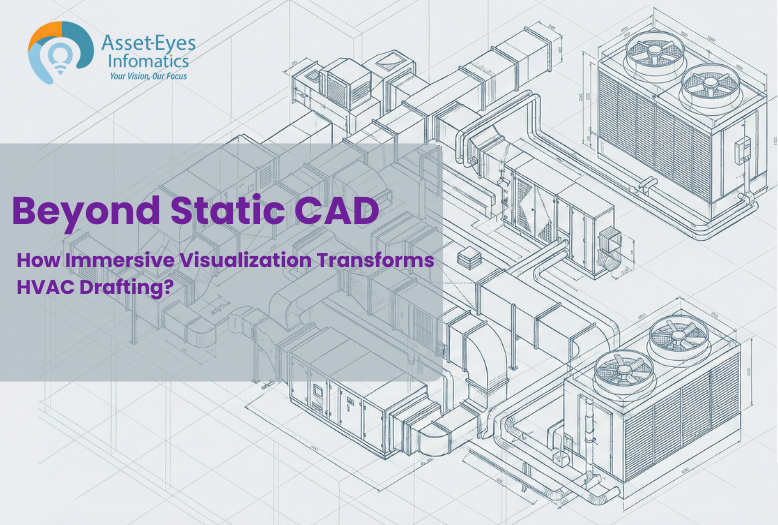

Have you ever tried explaining a complex air handling unit layout or chiller plant configuration using only 2D drawings and static screenshots? We know that trying to paint a picture of what a piece of equipment looks like in the real-world isn’t an easy task, especially to stakeholders who don’t come from a technical background.Traditional CAD drafting often fall short of communicating design intent effectively across diverse teams from engineers to production staff to field technicians.

This blog explores how immersive visualization technologies (VR/AR/XR/MR) are revolutionizing HVAC-R manufacturing by transforming static models into interactive experiences that enhance understanding, reduce errors, and accelerate project timelines. We’ll cover four practical applications you can implement immediately:

- Assembly guides

- Training manuals

- Sales demonstrations

- Shift handover processes

1. What Immersive Visualization Means for HVAC-R Manufacturing – CAD Drafting

Immersive visualization takes your existing CAD models and transforms them into three-dimensional, interactive environments that teams can explore, manipulate, and understand intuitively. You can “walk through” equipment rooms, examine component relationships from any angle, and identify potential issues long before they become expensive problems.

Virtual Reality (VR) creates completely digital environments where users can examine HVAC systems in detail without physical constraints. Your engineering team can virtually stand inside a mechanical room, checking clearances and access points before construction begins.

AR enhances your real environment by placing digital visuals over it. This is ideal for creating installation guides and maintenance procedures. Technicians can use their mobile devices to scan or recognize the equipment, triggering step-by-step AR overlays.

Extended Reality (XR) and Mixed Reality (MR) bridge the gap between “look but don’t touch” AR and fully interactive experiences. This proves invaluable for retrofit projects: imagine being able to “move” a virtual air handler around a real mechanical room until you find the perfect position that clears all the existing piping and provides proper maintenance access.

Using specialized goggles, the technician can “grab” a full-scale holographic air handler with their hands, physically move it around the real room to test different positions, and watch it correctly disappear behind real pipes and beams. They can even reach out and “open” virtual access panels to check maintenance clearance.

The Key Difference: AR shows you information about reality; MR lets you interact with digital objects as if they were physically present in that reality.

2. Four Game-Changing Applications for Your HVAC-R Operations

a. Assembly Guides That Eliminate Guesswork

Traditional assembly documentation often leaves technicians questioning component orientation, connection sequences, or tool requirements. Immersive assembly guides provide step-by-step visual instructions that technicians can follow in three dimensions, dramatically reducing assembly errors and production delays.

Consider a complex evaporative cooling system design assembly. Instead of flipping through pages of drawings, technicians use AR to see exactly where each component belongs, view proper connection methods, and instantly view the correct torque values for each connection right in their field of view. This approach captures tribal knowledge from experienced technicians and preserves it in interactive formats that new employees can access immediately.

Key drafting considerations:

- Maintain clear subassembly structure and consistent naming in your CAD drafting to drive clean step-by-step animations

- Use consistent part metadata (part numbers, materials, revision levels) to map callouts accurately in the immersive guide

- Align your solidworks 2D drafting with the 3D sequence to ensure documentation consistency

b. Training Manuals That Accelerate Learning

HVAC-R systems involve complex interactions between mechanical, electrical, and control components that are difficult to explain through traditional manuals. Immersive training lets technicians interact directly with their virtual environment; they can move, manipulate, and explore system components as if working on real equipment.

Trainees can virtually disassemble and reassemble equipment, observe refrigerant flow patterns, or practice troubleshooting procedures for industrial exhaust system design applications in safe, controlled environments. For motor control panel design training, technicians can explore wiring sequences and safety procedures without risk of electrical hazards or equipment damage.

Implementation benefits:

- Rapid onboarding for new technicians who can practice virtually before hands-on work

- Consistent training delivery across multiple locations

- Easy updates to reflect new products or revised procedures

c. Immersive Sales Demonstrations That Close Deals Faster

Selling complex HVAC equipment design solutions often requires helping customers visualize systems that don’t yet exist. Traditional presentations with static images and technical specifications struggle to convey the true value and functionality of your products.

Immersive sales demonstrations allow prospects to experience your solutions firsthand. They can walk through virtual mechanical rooms, observe how a system operates under different conditions, and understand maintenance access requirements before making purchasing decisions. If your prospect asks you for a visualization of a different configuration, you can show it to them right then and there. Sales teams can customize demonstrations on the fly, showing different configuration options or highlighting specific features that address individual customer concerns.

This experiential approach builds confidence and trust while differentiating your offerings from competitors who rely on conventional presentation methods.

d. Shift Handover That Prevents Information Loss

Traditional handover methods written logs, verbal briefings, or static documentation often miss critical details or fail to convey the full context of ongoing situations.

For instance, a night-shift technician might jot down that “Unit 3 showing high pressure,” but without photos, sensor data, or visual context, the incoming team has no idea that a valve was partially closed or that a temporary bypass was installed. Small oversights like these can lead to repeated troubleshooting or even equipment downtime.

Immersive shift handover systems allow outgoing teams to create visual records of current conditions, ongoing issues, or special considerations. Incoming shift members can virtually tour facilities, see exactly what the previous team experienced, and understand priorities without lengthy explanations or potential miscommunications.

Practical applications include:

- Visual state capture with notes pinned in 3D space showing what’s installed, what’s pending, and what needs rework

- Punch-list alignment with issues tagged directly on the model with photos and comments tied to part IDs

- Commissioning guidance that visualizes sensor placement, valve orientation, and test point access paths

3. Implementation Strategy for HVAC-R Manufacturers – CAD drafting

Successfully implementing immersive visualization requires understanding both technology capabilities and your team’s specific needs. The most effective implementations start with clearly defined objectives and realistic expectations about learning curves and initial investment requirements.

Hardware Selection:

- Headsets: Best for deep training sessions and comprehensive design reviews

- Tablets/smartphones: Ideal for shop floor applications and AR overlays

- Desktop viewers: Excellent for sales presentations and remote engineering collaboration

Change Control Integration: Tie immersive packages to drawing revisions so training, assembly, and sales content always reflect the latest approved state. This maintains consistency between your CAD drawings services and immersive experiences.

Performance Optimization:

- Right-size detail levels: Suppress cosmetic features that don’t add instructional value

- Use higher detail for maintenance training mechanisms; lower detail for mobile sales demonstrations

- Maintain consistent coordinate systems for accurate AR overlay alignment on-site

4. How Asset-Eyes Transforms Your Vision Into Reality – CAD Drafting

At Asset-Eyes, our immersive visualization services build upon our proven expertise in HVAC CAD drafting and solidworks designer services. We understand that exceptional technical documentation forms the foundation for effective immersive experiences.

Our comprehensive approach includes:

Foundation Services: We provide precise CAD drafting service that create manufacturing-ready documentation including detailed general assembly drawing, part specifications, and callout-rich documentation that your production and field teams can trust.

Immersive Transformation: Using your approved designs and specifications, we transform those models into interactive visualization experiences that support all four key applications: assembly guides with step-by-step 3D sequences, training manuals enriched with interactive procedures, sales demonstrations that help customers understand options and access requirements, and shift handover systems with 3D-pinned notes and status tracking.

Clear Service Boundaries: You maintain complete ownership of design decisions and performance criteria. Asset-Eyes delivers precise drafting and immersive content that communicates your intent clearly to manufacturing, sales, and service teams without altering your design specifications.

Our expertise in both traditional solidworks 2D drafting and cutting-edge immersive technologies ensures seamless integration with your existing workflows while opening new possibilities for communication and collaboration.

The Competitive Advantage of Immersive Communication

Immersive visualization isn’t just impressive technology, it’s becoming a competitive necessity. Manufacturers who embrace these tools early on gain significant advantages in team training efficiency, customer engagement quality, and operational accuracy. As hardware costs decrease and software capabilities expand, the barriers to implementation continue to lower.

You no longer have to experience the frustration of watching installation delays unfold because teams interpreted documentation differently, or shell out for expensive field modifications because novice technicians couldn’t visualize how components fit together in practice.

The most successful implementations focus on solving specific communication challenges rather than adopting technology for its own sake. Whether you’re struggling with assembly errors, training inefficiencies, sales presentation limitations, or shift communication gaps, immersive visualization opens the door to practical solutions that deliver measurable results.

Ready to move beyond static mechanical CAD drafting services and transform how your team communicates complex HVAC-R designs? The technology is proven, the benefits are clear, and the competitive advantages are waiting for manufacturers bold enough to embrace the future of design communication.

Conclusion

Immersive visualization is no longer a futuristic concept, it’s a practical, high-impact solution that improves how HVAC-R teams design, communicate, and execute projects. By turning your CAD models into interactive 3D experiences, you eliminate miscommunication, reduce rework, and help every stakeholder from engineers to technicians to customers understand the design clearly and confidently.

As the HVAC-R industry moves toward smarter, faster, and more precise operations, adopting immersive tools gives you a real competitive edge. If you’re ready to transform your workflows, enhance team training, and deliver projects with greater accuracy, now is the right time to embrace immersive visualization.

Contact Us Now:

📞 +91 9840895134