Has your team ever tried pulling a compressor out of a rooftop chiller skid at 3 AM during an emergency repair? If you’ve experienced the frustration of tight clearances, expensive crane rentals, and extended downtime, you’re not alone. The difference between a well designed lifting system and an afterthought can mean the difference between a two hour repair and a two-day ordeal involving external equipment, street permits, and frustrated facility managers. This post walks through how we created an integrated lifting mechanism that transforms chilling design skid maintenance from a logistical nightmare into a streamlined process with no external crane required.

1. The Challenge: When Space Meets Weight

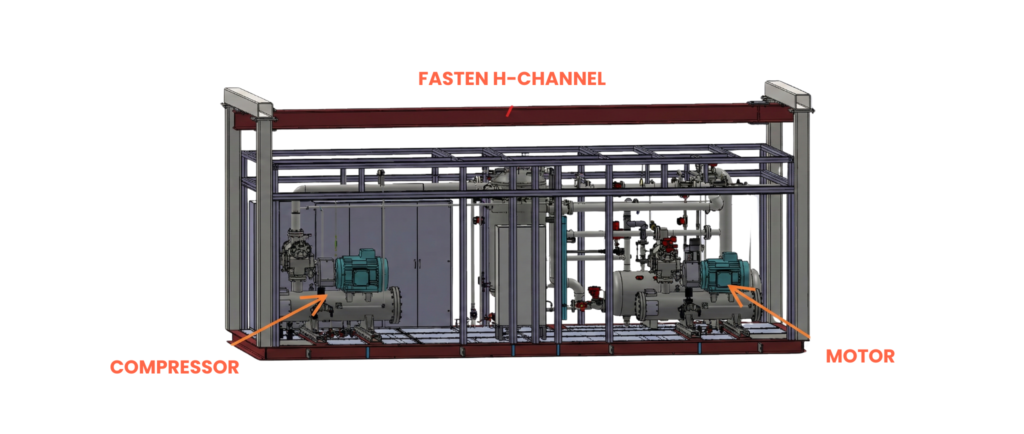

Modern chilling design skids present a unique challenge that goes beyond simple component arrangement. These systems must pack substantial cooling capacity into increasingly compact footprints, often destined for rooftop installations where space is at a premium. The result? Major components like compressors and motors end up positioned in tight quarters that make routine maintenance a logistical headache.

Consider the typical scenario: a compressor weighing over 500 kilograms sits nestled between structural elements. With barely enough clearance for technicians to access connection points, let alone remove the entire unit. Traditional maintenance approaches create several pain points that affect both immediate costs and long-term operations. External lifting equipment often can’t fit through building access points, hoists require additional structural support that may not be available. And manual lifting methods create safety risks while increasing downtime at the same time.

Immediate repair costs are not the only financial implications. Extended downtime affects routine building operations. Pair this with the unexpected expense of renting external equipment, and the disruption keeps mounting. That’s a big burden on facility managers operating multiple sites.

2. The Solution – Integrated Lifting Mechanisms – Chilling Design

Our approach to this challenge involves designing the lifting capability directly into the skid structure from the outset. Rather than treating component removal as an afterthought. Integrated lifting mechanisms make maintenance accessibility a core design parameter that influences the entire system layout. This proactive approach to HVAC equipment design transforms a potential headache into a competitive advantage.

We engineered two alternative mechanisms to achieve this integrated lifting capability, each suited to different spatial constraints and operational requirements:

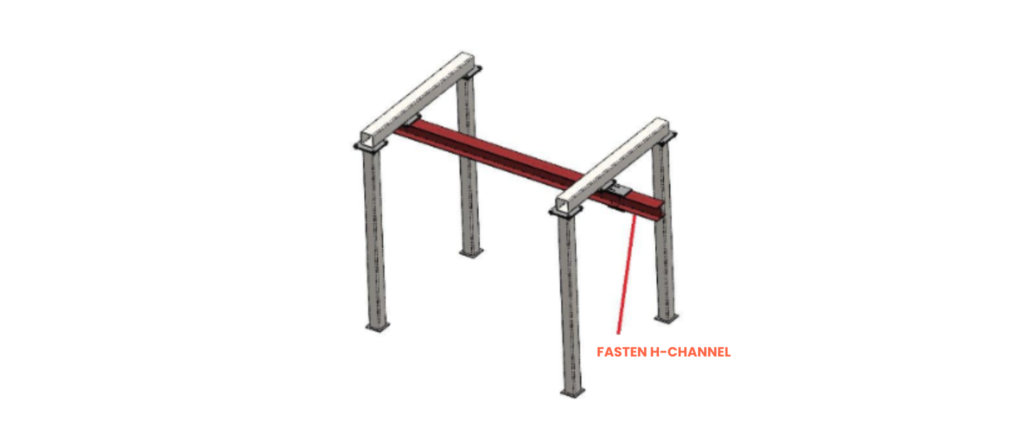

I. Corner Pillar Concept:

This design uses four 5-inch square tube pillars and two 6-inch crossmembers with a permanent H-channel connecting the compressor and motor tops. During maintenance, a temporary H-channel extends the rolling path. Allowing the entire assembly to move horizontally out of the skid using integrated rollers. This eliminates overhead clearance requirements, and the temporary channel is removed after service.

II. Single Bearing Davit Arm:

This design adds a 6-inch H-channel pillar at the skid’s corner with a hinged horizontal H-channel attachment. The integrated roller system moves the compressor and motor linearly along the horizontal channel. Then the hinge mechanism rotates to swing the entire assembly outside the skid on the larger door side, providing clear access for maintenance operations.

Both approaches share common design principles that ensure reliability and safety while eliminating the need for external lifting equipment. The mechanisms must handle not just component weights. But also dynamic loads associated with lifting operations, wind loading in rooftop environments, and additional safety factors required for personnel working beneath suspended loads.

III. Force Calculations: Engineering the Foundation

Proper engineering of integrated lifting systems requires careful analysis of the loads involved and the operating conditions where these systems will be used. For this particular chilling design configuration. The primary loads come from the compressor and motor assemblies that represent the heaviest components requiring periodic removal.

Using standard gravitational acceleration factors, the force calculations provide the foundation for all structural and mechanical design decisions:

Compressor Force = 542 × 9.807 = 5315 N

Motor Force = 1072 × 9.807 = 10513 N

Total Load: ≈ 16,000 N

These calculations represent just the static loads the actual design must account for dynamic factors including acceleration during lifting, potential impact loads, and environmental conditions. Rooftop installations face additional challenges from wind loading, temperature variations, and the need for personnel safety during maintenance operations. These factors typically result in design loads that are significantly higher than the basic component weights. Ensuring the lifting mechanisms can operate safely under real-world conditions.

3. Critical Drafting Considerations That Make It Work

The successful implementation of integrated lifting mechanisms requires comprehensive CAD drawings services that capture both the structural requirements and operational procedures. Our role in creating manufacturing ready documentation focuses on several key areas that ensure safety, buildability, and long term reliability.

I. Load Path Clarity:

We tie lifting loads into primary skid channels, not secondary sheet metal, detailing gussets, doubler plates, and weld sizes so loads travel directly into the frame. This requires careful coordination between the lifting mechanism design and the overall skid structure to ensure forces are distributed appropriately throughout the system.

II. Center of Gravity Mapping:

Through detailed SolidWorks designers modeling, we locate compressor and motor centers of gravity and draft lift points, arm reach. And clearances to keep loads within stable envelopes during lifting and swinging operations. This analysis prevents dangerous load shifts that could compromise safety or damage equipment.

III. Motion Studies and Service Clearances:

We use motion studies within our solidworks drafting services to check swing arcs, interference patterns, and technician access requirements. These studies identify potential conflicts before manufacturing begins, ensuring that the lifting mechanisms can operate effectively in their intended environment.

IV. Connection Details:

Pin sizes, locking plates, detent holes, and keeper chains are all specified to make field use safe and obvious. The documentation must clearly show how components connect. lock in position, and store when not in use, reducing the likelihood of field errors or safety incidents.

V. Environmental Considerations:

We specify appropriate finishes such as galvanizing or powder coating callouts and incorporate water-shedding details for rooftop exposure. The harsh environmental conditions where these systems operate require careful attention to corrosion protection and weather resistance.

VI. Assembly and Installation Guidance:

Our general assembly drawing packages show how mechanisms ship. Where they store on the skid, and how they’re assembled on-site with standard tools. This documentation reduces installation complexity and ensures consistent, safe assembly across multiple units.

4. Implementation Benefits and Operational Value

Integrated lifting mechanisms deliver value that extends well beyond the immediate maintenance operation. From a lifecycle cost perspective, these systems reduce total ownership costs by eliminating external equipment rental, reducing maintenance time, and enabling more frequent preventive maintenance that can extend component life significantly.

The operational benefits are equally compelling. Maintenance teams can perform component removal with standard tools and procedures, without specialized external equipment or additional personnel. This predictability allows for better maintenance scheduling and reduces the likelihood that minor issues will escalate into major failures due to deferred maintenance. Facility managers gain the ability to plan maintenance windows more effectively. Knowing that equipment access won’t depend on external crane availability or weather conditions.

From a design perspective, incorporating lifting mechanisms early in the development process often leads to better overall system layouts. The requirement to provide clear lifting paths encourages designers to consider component accessibility throughout the design process, resulting in systems that are more maintainable in all aspects, not just for major component removal.

5. Asset-Eyes’ Role in Bringing Innovation to Life – Chilling Design

As a specialized CAD drafting service provider, our role is to transform innovative concepts into precise, buildable documentation that supports both manufacturing and long-term maintenance operations. We don’t provide final engineering sign-off, performance guarantees, or code certification; those responsibilities remain with our clients’ engineering teams. Instead, we ensure that complex design decisions are translated into clear, accurate drawings that eliminate guesswork during fabrication and assembly.

Our HVAC CAD drafting expertise enables us to create comprehensive documentation packages that include detailed assemblies with motion checks, exploded views for complex mechanisms, part drawings with complete material specifications and tolerances, service clearance drawings that show operational envelopes, and rigging diagrams that guide safe lifting procedures. Through our solidworks drafting services, we help manufacturers create systems that are not only innovative but also practical to build and maintain.

The integration of lifting mechanisms into chilling design represents a broader industry trend toward designing for the complete equipment lifecycle rather than just initial performance specifications. This approach recognizes that true equipment value extends beyond cooling capacity to include factors like maintainability, operational reliability, and total cost of ownership. For manufacturers developing similar systems, the key insight is that maintenance accessibility must be considered as a primary design requirement from the earliest stages of product development.

6. Results You Can Expect – Chilling Design

When properly implemented and documented, integrated lifting mechanisms transform the maintenance experience in measurable ways. Maintenance turnarounds become faster and more predictable because the lifting capability is exactly where it’s needed. Dependence on external crane scheduling for routine component swaps is eliminated, reducing both costs and scheduling complexity. Most importantly, procedures become safer and more repeatable, supported by clear drawings and operational guidance that reduce the risk of field errors.

The success of this approach demonstrates that thoughtful design, backed by expert drafting, can truly simplify complexity while creating competitive advantages for equipment manufacturers. By considering the complete equipment lifecycle during the design phase, manufacturers can create systems that deliver superior value to their customers while establishing new standards for industry best practices.

At Asset-Eyes, we’re committed to helping HVAC manufacturers create documentation that supports both innovative design and practical implementation. Our experience with complex machine design projects enables us to understand the unique challenges of integrating maintenance features into production equipment while maintaining the clarity and precision required for successful manufacturing.

Conclusion

Modern chilling design demands more than compact layouts and high performance. It requires an understanding of how systems are maintained under real-world conditions. Integrated lifting mechanisms demonstrate how planning for maintenance early can prevent costly delays and operational disruptions later.

Through precise CAD drafting and clear service documentation, these solutions become dependable tools rather than improvised fixes. By focusing on the full equipment lifecycle, manufacturers can deliver chiller systems that are easier to maintain, safer to service, and more valuable over time.

Contact Us Now:

📞 +91 9840895134